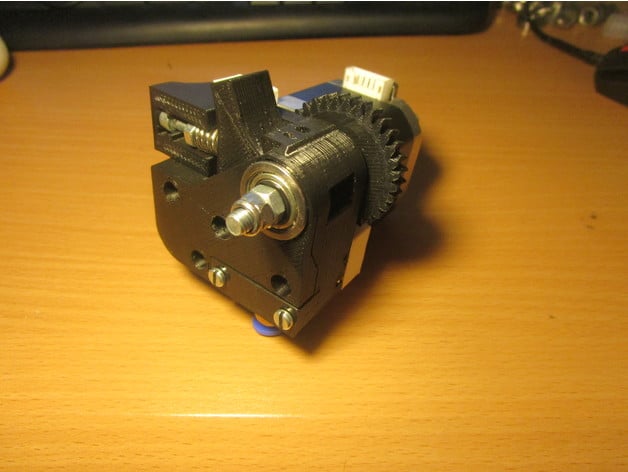

NSTT Extruder

thingiverse

This is the NSTT Extruder. Revision 2 now available. I've designed this extruder in December 2016 and after some heavy testing and redesigning, I decided to share it. NSTT stands for "Not So Tiny Titan" and is an E3D Titan-inspired printable extruder. Despite its name, it's a pretty compact geared extruder when compared with other geared extruders. It has the same 3:1 gear ratio as the E3D Titan. I incorporated parts from my initial MK8 extruder, like the spring, the hobbed gear, and the 623z bearing. To build this, you'll need: -4x M3x10 screws and nuts -1x M5x40 screw (Hexagonal head) and an M5 nut -5x M3x25 screws and nuts -1x M4x20 screw (internal hex head) and a nut -2x 625ZZ bearings or 688ZZ/F688ZZ bearings Assembly is straightforward. Insert the small gear into the stepper shaft, which will self-lock. Next, attach the motor mount to the stepper using M3x10 screws. Then, insert the big gear, followed by the bearing, spacer, and hobbed gear for option 1 (625 bearings). For option 2 (688 bearings), use the 688 spacer instead of the 625 spacer. Mark where the side screw hits the M5 screw, remove it, and use a tool file to create a dent. Reassemble everything and tighten the MK8 hobbed gear in place. Connect the two printed gears and insert the extruder body, making sure the bearing fits into the main body slot. You may need to adjust the small printed gear's position for proper alignment. Screw the extruder body to the base using M3x25 screws. Assemble the filament idler by inserting the 625 bearing (if using option B) and attaching it to the back of the idler with an M3 nut, washer, and 623 bearing. Place the MK8 tension spring in the M4 screw, following the pictures for correct placement. Fit the idler into the stepper shaft and place the filament guide in its designated spot. Screw the extruder lit in place, followed by the rest of the shaft parts: 625 spacer B, 625 bearing (for option 1), or 688 bearing (for option 2). Tighten everything with an M5 nut, then add the M5 nylon lock nut on top. Be careful not to load the bearings too much. For optimal performance, use the E3D in direct feed mode or print the adapter for pneumatic coupler installation as a bowden extruder. Configure Marlin's E steps/mm to about 440 and test it, adjusting as needed. Enjoy your new geared extruder – the printing quality is well worth it! Printer Settings: - Printer: P3Steel - Rafts: Doesn't Matter - Supports: Yes - Resolution: 0.25mm - Infill: 50%

With this file you will be able to print NSTT Extruder with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on NSTT Extruder.