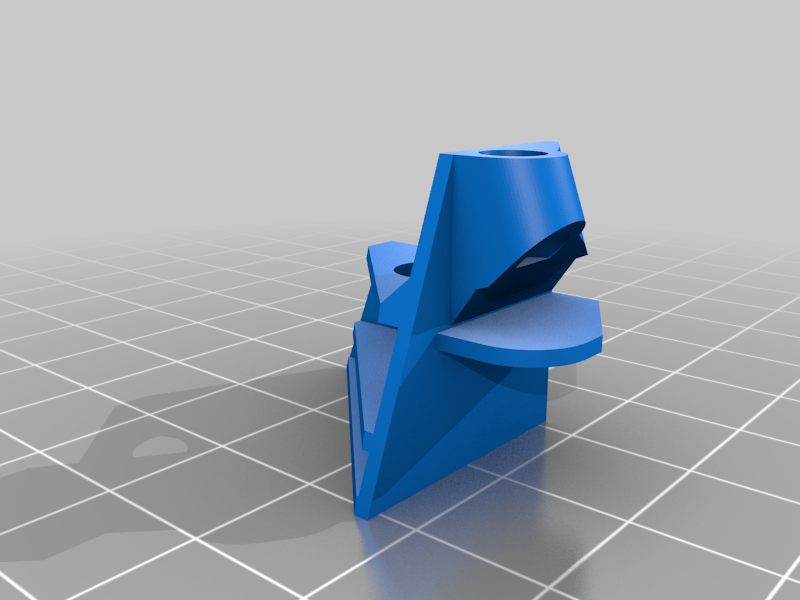

Nozzle Wiper for Anycubic I3 Mega

thingiverse

Project has been completed. Major issue - wiping with tube is not very effective due to clogging of the filament in the tube, and various filaments require different amounts of drain. For experimenters like me, it remains available (it works fairly well). Nozzle cleaner/wiper for quick print start (even without skirt). Using a piece of PTFE tube, mounts to the front-left corner of the bed. For proper functioning, it needs special starting code in the slicer (cura script below). Print holder on the right side, so no support is necessary. 0.2 layer height is okay. Use ABS - it touches the hotbed. Probably you will need to cut off some soggings and clear a hole for PTFE tube with a 4mm drill. Just don't drill out the stopping step at the bottom of the hole! It's needed for the tube not to be pushed down by the nozzle. To install: 1. Unscrew left and right screws at the front of the bed. Install printed part as in the photo. Then level the bed to your normal state. 2. Insert PTFE tube and cut about 1mm above bed. 3. Bend X endstop a little, so nozzle can reach center of tube. Careful - don't overbend it so X-carriage will hit Z. Home all axes. 4. Using printer menu set nozzle directly above center of PTFE tube. Go to Setup - Status and write down XY coordinates. It will be something like X 4.5 Y-6.0. 5. Using printer menu set nozzle barely touching wall of PTFE tube at side facing bed. Write down Z coordinate. It will be about 0.6-1mm (depends how you cut the tube). Now correct the starting script below: Find strings "G0 X-4.4 Y6 ;X/Y position nozzle over PTFE tube G0 Z0.4 ;Z position nozzle into PTFE tube" In first string insert X/Y coordinates you got at step 4. In second string insert value you got at step 5 MINUS 0.2 (so nozzle will hit the wall, and cleans itself. For example, you got 0.9 at touching. So string will be "G0 Z0.7" Script is for Cura: G21 ;metric values G90 ;absolute positioning M82 ;set extruder to absolute mode M107 ;start with fan off G28 Z0 ;move Z to min endstops G0 Z3 ;move Z to +3 to avoid PTFE tube G28 X0 Y0 ;move X/Y to min endstops G0 X-4.4 Y6 ;X/Y position nozzle over PTFE tube G0 Z0.4 ;Z position nozzle into PTFE tube G92 E0 ;zero extruded length G1 F100 E10 ;slowly extrude 10mm of feed stock G1 F2400 E8.5 ;fast little retract to release pressure G92 E0 ;zero extruded length again G0 X3 F1500 ;move over tube edge, and we ready to go WIP warning: This system is not fully tested. I don't know how long will PTFE lasts, and script is not quite flawless. Probably I'll change the extrude-retract string values, and add some additional moves over tube for better cleaning.

With this file you will be able to print Nozzle Wiper for Anycubic I3 Mega with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Nozzle Wiper for Anycubic I3 Mega.