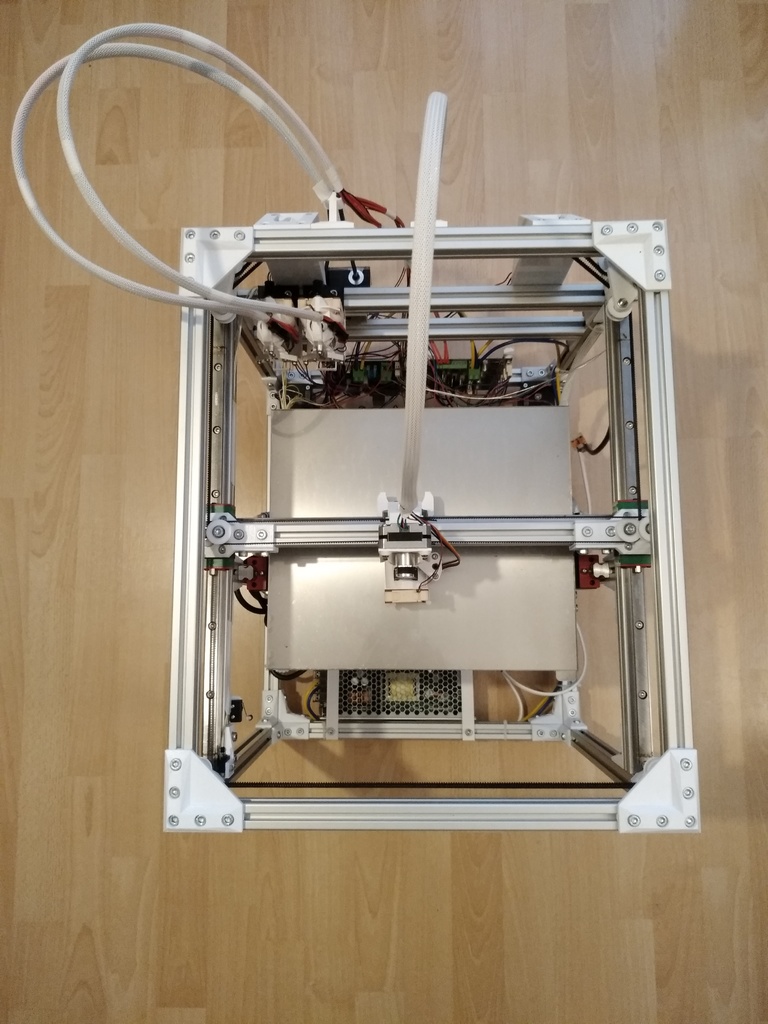

Non Sucking 3D Printer Mk2

thingiverse

UPDATE 2020-01-13: The final locking mechanism is complete. A simple M5 screw driven by a stepper motor secures the toolheads in place. Each toolhead has a matching M5 nut. Watch it in action here: https://www.youtube.com/watch?v=KpfY1AHpZh4 UPDATE 2019-10-20: Progress update: yes, I'm still working on this project. After finally getting my milled aluminum parts, I discovered that my initial locking mechanism for the toolchanger won't work as planned. I'm currently testing alternative solutions that are both reliable and affordable. Once I find a suitable solution, I'll update the files here. UPDATE 2019-03-30: Sorry for the late update! I've completely revamped the file structure to be more modular, improving rendering time and performance in the preview. The print head and carriage have undergone several updates and test prints, while the X-gantry mounts to the Y wagons are now sturdier. The bed leveling mechanism has been optimized for M4x1x20mm washers, ensuring that the load is carried directly on the aluminum extrusion instead of plastic. UPDATE 2018-09-23: I've added blocks to fit into the aluminum extrusion slots on all parts. I've resized the filament drybox to match the updated size of the printer. I've also added stacking corners to the filament drybox for safe stacking of the printer on top. Additionally, I've made the E3D groove mount slightly elliptical for easier mounting and vertically adjustable by sliding it up or down. UPDATE 2018-09-15: I've removed the filament storage drybox for now; it will be added later. I've resized the printer to accommodate the upcoming syringe extruder. The kinematic coupling has been enlarged for increased stability. I've prepared everything for the syringe extruder and started designing it, as well as preparing the extruder mounts and starting their design. UPDATE 2018-09-05: Nearly finished version with filament storage drybox, bed leveling screws, Z motors, and print head parking position holders. The "single part export" code needs updating; I'll do that in a few days. After using the original NS3DP for a while, I noticed several features that bothered me and weren't easy fixes but rather significant changes. So, I decided to build a new one. What E3D showed with their tool changer intrigued me, so I wanted to include it too, but with some differences. The Z-height of the nozzle on every tool in my printer will be exactly the same; no software compensation is needed. In the parking position, the nozzles should sit over an ooze/dump zone and each move into and out of that zone should go over a brush to keep the nozzle clean. Four tools aren't enough for me, so I went with seven – the maximum a Duet3D can do with the Duex5 expansion board. Learning from the mistakes of the previous printer, the whole thing will be designed in OpenSCAD (I'm never going back to Sketchup). The print volume will be smaller (300x250x200), the linear rails will be recirculating ball linear rails from Hiwin, it'll be a CoreXY because Ultimaker-style can't store tools at the side. It'll also get a BLtouch bed sensor and some parts will have to be machined from metal. I'll keep those to a minimum because I know that makes the printer harder to build for you guys out there, but some parts just have to be metal.

With this file you will be able to print Non Sucking 3D Printer Mk2 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Non Sucking 3D Printer Mk2.