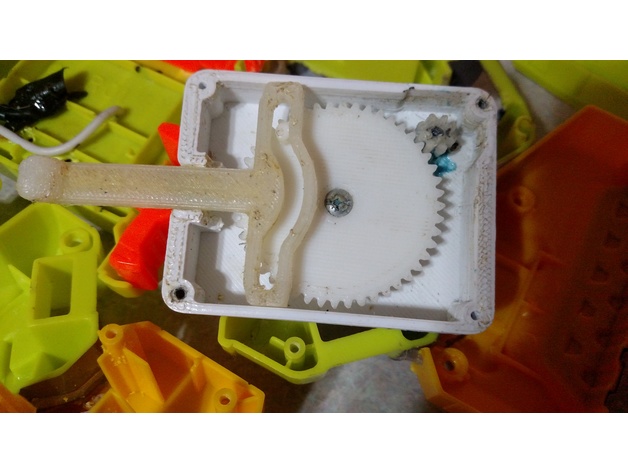

Nerf High Speed Automatic Dart Pusher Mechanism

thingiverse

This is a dart pusher mechanism for a full auto Nerf blaster that delivers a higher rate of fire due to its lower gear ratio compared to the stock pusher mechanism. The design has been modified from a previous creation by blasterforgePH to enhance reliability and minimize part breakage. Print Settings Printer Brand: Printrbot Printer: Printrbot Simple Metal Rafts: No Supports: Yes Resolution: 0.4mm Notes: Internal parts were printed at 100% infill, while the case was printed at 15% infill. It's recommended to print gears and pusher arm with a stronger material than PLA for improved durability; nylon was used for Gear A and the pusher arm. Gear B is the only part requiring supports. Other necessary components include: -1 #6-32 screw -4 #2-56 screws -1 pinion gear from a Blade 180 or Xtreme Pro 180 motor -A small amount of epoxy -2 screws for motor mounting (M2x4mm flat countersunk screws) -Hot glue -Threadlocker or nail polish A #6-32 screw is required to secure the main gear; it must be glued in place, as otherwise the gear will turn the screw and affect mechanism functionality. Mounting screws are necessary for attaching the motor, while 4 screws (similar to those found in a Nerf blaster) are required to hold the case's two halves together (#2-56 screws should work). The new version of Gear A features a metal pinion gear, epoxied to its inside, which addresses an issue where the gear would slip off the motor axle and be damaged when printed with PLA. The metal gear should be secured to the motor axle using threadlocker or nail polish. Post-Printing Demonstration: The above video showcases a blaster firing 12 darts using this mechanism; it utilizes Xtreme Pro 180 motors. Note that this pusher mechanism requires motors with significant torque, such as Xtreme Pro 180 motors, for the pusher motor and flywheel motors. Compatible Blasters (So far) Rayven: This is the blaster featured in the demonstration video. The pusher box can be used in the Rayven by cutting holes in its shell. Stryfe: A test fit of the mechanism without the motor has been completed; it has since been successfully implemented in a Stryfe. Possible future updates: -External box to secure the motor in place -New version of Gear B that utilizes a screw instead of the 3D printed nub on top of the gear to move the pusher arm

With this file you will be able to print Nerf High Speed Automatic Dart Pusher Mechanism with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Nerf High Speed Automatic Dart Pusher Mechanism.