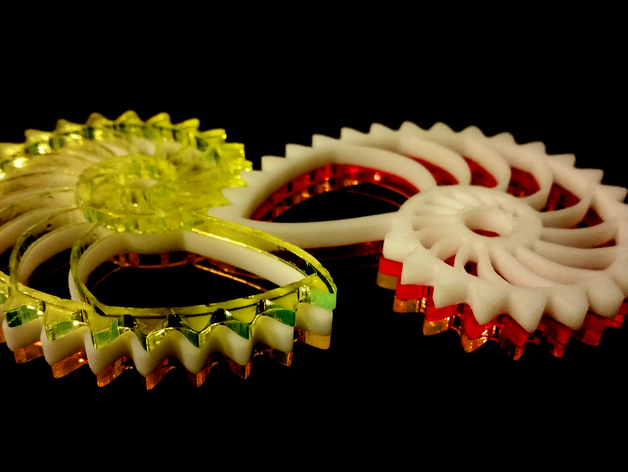

Nautilus Gears Acrylic laser cut + 3d print

thingiverse

I envisioned a fresh take on the Nautilus Gears that would add some vibrancy to the overall design. To accomplish this, I turned to acrylic, as I already have access to a precision laser cutter at my disposal. When handling the edges of any acrylic component, I highly recommend employing fine-grain sandpaper for safety purposes. By smoothing out the sharp edges, you'll significantly reduce the risk of cuts and injuries. Let's dive into how this project unfolded: Firstly, I initiated the process by importing the original Nautilus_Gear.STL file into PyCam, where it alerted me to the presence of numerous invalid triangles within the design. To rectify this issue, I took the liberty of importing the file into Blender and applying the decimate modifier. This resulted in a significantly optimized design, culminating in an astonishing 85% reduction in file size – from a formidable 1.7 MB down to a mere 173.8 kB. In doing so, it became abundantly clear that simplicity reigns supreme when it comes to 3D printing or laser cutting: the less complex your project, the fewer hurdles you'll encounter. My tinkering eventually yielded Nautilus_Gear_decimatedHALF.STL – a streamlined masterpiece that's easier on your tools. Now, when it came time to fabricate the acrylic components, I chose to rely on my trusty laser cutter and employed the original Nautilus_Gear.svg file as the guiding blueprint. In generating this svg, I utilised slic3r's innovative Slice to SVG function in tandem with the original Nautilus_Gear.STL file. As you'll quickly discover, it's often significantly more efficient to cut intricate 2D components on a laser printer than attempting to use a 3D printer – trust me on this one.

With this file you will be able to print Nautilus Gears Acrylic laser cut + 3d print with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Nautilus Gears Acrylic laser cut + 3d print.