multistage peristaltic pump - cheap and simple

thingiverse

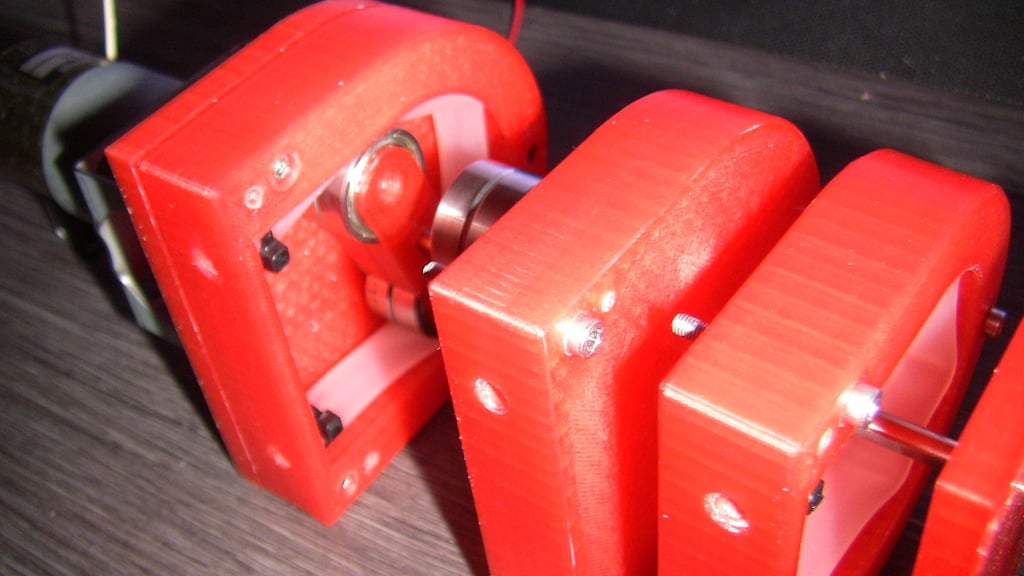

In my apartment, a collection of plants sits precariously on an overhead shelf, their weight making it difficult to water without spilling most of the liquid. I had been searching for a peristaltic pump, but all I could find were basic pumps that require a geared motor for each one. So, I decided to create a multistage pump, allowing users to combine as many peristaltic stages as they like. To assemble the pump, you will need the Alpha_und_Omega.stl file, which serves as a baseplate for fixing the geared motor and bearing on the driveshaft. The three small holes on the outside are threaded for M3, while the four in the center are suited for M4. The bearings for the baseplate are simple 606ZZ bearings. I used an old 24V SAYAMA RB-35GM-E35-24 motor, but it's unclear where one could purchase a similar geared motor to fit on the baseplate or create their own from scratch. For the driveshaft, I utilized a 6mm axle and ground a face of about 1mm from one side for its full length using an angle grinder. It is connected to the motor via a shaft coupling found in my workroom. Each peristaltic stage requires one Flik-Flak-Gehaeuse.stl file and two Rotator.stl files. The Rotator.stl needs four bearings 608ZZ, two hex socket screws M3x10, and two hex nuts M3 to assemble properly. After printing the Flik-Flak-Gehaeuse.stl, the three small holes on the outside must be threaded for M3. Then, insert a 6mm flexible tube through the input-/output holes as needed. Next, cut a 150mm length of 6/10mm silicon hose and place it above the 6mm tube. I secured them air-tight with small zip ties, which works well! To add another stage, simply print Flik-Flak-Gehaeuse.stl and two Rotator.stl files again. Modify them as outlined above and screw the assembly upside down to the first stage using three hex socket screws M3x25. You can repeat this process up to the length of your driveshaft or until your motor becomes too weak. This project is still in its development phase, so feel free to share any ideas or suggestions for improvement! Summary (one stage): * 2 x 606ZZ * 4 x 608ZZ (per stage) * 3 x hex socket M3x25 (per stage) * 2 x hex socket M3x10 (per stage) * 3 x hex socket M3x16 * 2 x hex nut M3 (per stage) Required components: * Geared motor * Driveshaft * Shaft coupling * 6mm flexible tube * 150mm 6/10mm silicone hose (per stage) * 2 zipties (per stage) Print without support and have fun! Special thanks to Gazorpa for proofreading and correcting all my texts. Update: I've added a Rotator for a 3mm wave and a Flik-Flak-Gehaeuse for another geared motor. An adaptor for a NEMA17 motor is coming soon! Update: I've updated the design by adding bigger Flik-Flak-Gehaeuse, which requires less filament and printing time. Additionally, I've added a bigger Rotator for a square driveshaft with 4.5mm diameter and round 6mm driveshaft.

With this file you will be able to print multistage peristaltic pump - cheap and simple with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on multistage peristaltic pump - cheap and simple.