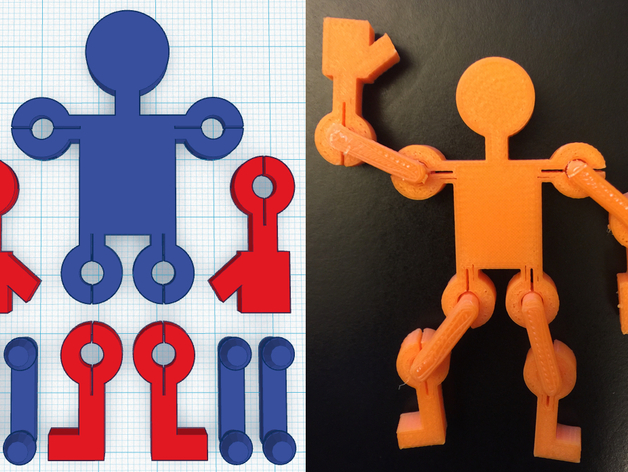

Movable Figure

thingiverse

This movable figure consists of eight joints that can swivel 360 degrees in every direction. The model itself comprises nine pieces that snap together quickly, usually within one minute. The idea for this model originated from a simple experiment with snap-fit connectors. I discovered an online tutorial on cantilever snap-fits and decided to give it a try as a one-dimensional axis. After experimenting with it a bit, I then expanded the concept radially so that the connection could pivot freely. I printed a single pivot connection initially, which turned out to be quite impressive. This led me to create this little figure, and to my surprise, it turned out even better than expected! The model in the picture was printed using a FlashForge Creator Pro 3D printer with generic ABS filament extruded at 220C onto a heated bed set at 110C. I designed the model using TinkerCad software, sliced it with Simplify3D, and printed it via OctoPrint. To add some extra stability, I included a raft (which was not necessary) and very small supports (which were probably unnecessary but caused some issues during removal). The post-processing involved simply removing the supports and trimming away any excess bits of filament. Feel free to use the snap-fit connector in your own projects. Here are a few notes about the model, specifically regarding the snap-fit connection: 1. Many types of snap-fit connectors are designed to be reversible with a release mechanism. However, this particular design is not. If you try to pull the shaft out of the housing after it connects, there's a good chance that the shaft will break. 2. A standard snap-fit connection works by allowing the outer portion to flex outward during insertion. In contrast, this radial connection doesn't allow for such flexibility because the outer portion is a solid disc. To overcome this limitation, I split the outer portion with a longitudinal seam that can flex outward during insertion and then snap back together when fully inserted. 3. When the connector is fully inserted, the end of the shaft protrudes slightly through the bottom of the connection. As a result, the figure doesn't lie flat in this case; instead, it rests on eight nubs protruding through the bottom. While this isn't an issue for this model (in fact, the eight points balance the mass of the figure well and add to its freedom of movement), you might need to extrude the bottom portion of the connector housing by a millimeter or two in other projects to ensure that the bottom of the housing is coplanar with the end of the shaft.

With this file you will be able to print Movable Figure with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Movable Figure.