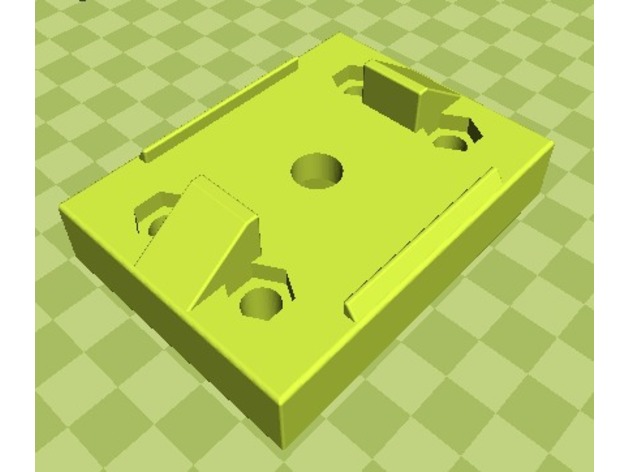

Mounting Plate for Rotacaster 48mm OmniWheel

thingiverse

We needed a way to attach 48mm Rotacaster wheels to our battery shelf so we could move it around the warehouse efficiently. We created this custom 3D printed part to fit between the steel RotaCaster housing and the foot of the battery shelf. It fixes together using countersunk nuts on each join, with a central hole for a 10mm bolt that is countersunk into the part. Each corner has 6mm holes serving a similar purpose. We attached this plate to the RotaCaster wheel housing and secured it to the base of each of our four-legged battery rack's legs. I used a pen, paper, digital callipers, and Fusion 360 to design the model, adding triangular guides to hold the shelf foot in place. If you need more information or have questions, feel free to ask. Printer Settings: Printer Brand: LulzBot Printer: TAZ 6 Rafts: No Supports: Yes Resolution: 0.15 Infill: 50% Notes: I oriented the print so that the central countersunk hole faced downwards on the print bed and only printed supports in that area. The standard supports from Cura worked perfectly and were easily removable. I used 50% infill because the shelf is holding a stack of LiPO batteries, and I didn't want to risk any issues. I also printed with brims (10 lines) and used ABS Plastic as it won't deform in hot summer temperatures. The wheels worked flawlessly, and now our battery shelf can move around the warehouse just as intended. How I Designed This: Step 1: Measure I measured the holes of the RotaCaster mounting plate and the dimensions of the foot of the shelf using digital callipers. Step 2: Fusion 360 My first model was based on my measurements, and it was purely to test if the size of the printed holes would match the screws I was using. I created a sketch profile in Fusion of the mounting profile (measured from this product: http://www.rotacaster.com.au/shop-product/48mm-mounted-solutions---r2/rotacaster-48mm-double--90a--firm-polyurethane-roller---fork-mounted). I extruded it to be around 10mm thick and then added countersunk hex-head bolts. Step 3: Print, Measure, Print again I printed the part on quick settings and tried to fit my bolts into the holes. They were all about .5mm too small, as were the hexheads. So I widened the holes in Fusion, also making the entire part thicker and broader than before because it wouldn't be stable with just the mounting plate profile. I reprinted that part on Standard quality quick print profile for ABS in Cura and found all dimensions perfect. However, the single bolt holding the shelf to the wheel didn't seem strong enough. Back to Fusion! I added the triangular guide rail to the top of the part, which holds the 3mm steel foot of the shelf perfectly in place. I reprinted the part at .15 Layer height and with all bells and whistles as a final prototype. SUCCESS after this; I multiplied the object in Cura and used the same print settings to make three more. I got my bolts from the local hardware store. The wheels are now installed on the shelf, and it can roll around the warehouse in any direction, looking incredibly stable!

With this file you will be able to print Mounting Plate for Rotacaster 48mm OmniWheel with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Mounting Plate for Rotacaster 48mm OmniWheel.