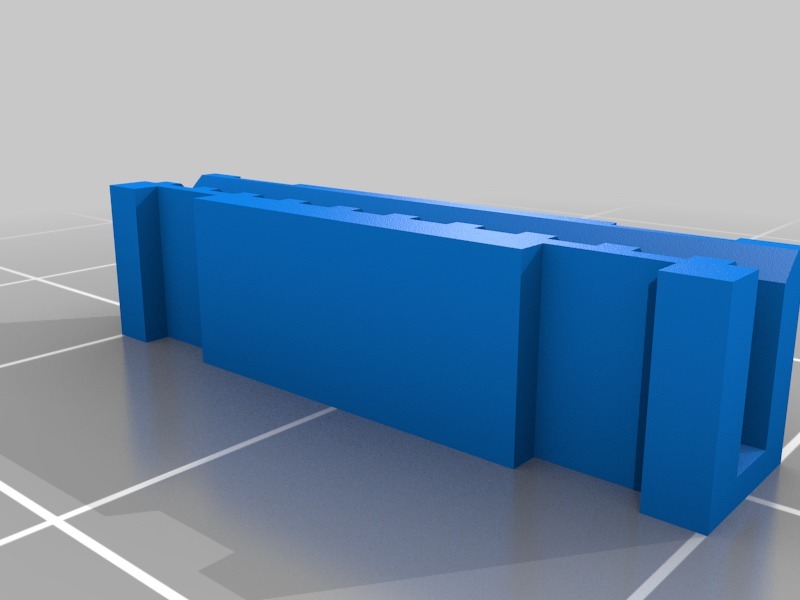

MONOPRICE MINI DELTA BELT JOINER

thingiverse

Fixing a Mini Delta Belt Defect or Broken Belt Made Easy If your sewing machine's Mini Delta belt is defective or broken, don't worry - fixing it is quicker and easier than you think. A simple replacement process can have your machine up and running in no time. In this article, we'll walk you through the steps to fix a defective or broken Mini Delta belt, so you can get back to sewing with ease. To start, gather all the necessary tools and parts before proceeding. This includes the new Mini Delta belt, a screwdriver, and possibly some wire cutters. Depending on your specific machine model, additional parts may be required. Make sure to consult your user manual for specific instructions. Next, locate the broken or defective Mini Delta belt. It's usually attached to the machine's motor or tension unit. You'll see two screws holding it in place - remove these with a screwdriver. Be careful not to touch any electrical components during this process. Once the old belt is removed, inspect the area for any debris or dirt that may have accumulated. Use a soft brush or cloth to clean out any obstructions. This will ensure a smooth installation of the new belt. With the area clean, proceed to install the new Mini Delta belt. Align it properly and secure it with the two screws you removed earlier. Make sure they're tightened firmly but not over-tightened. Finally, test your machine by sewing a few straight lines or a simple project. If everything is working as expected, congratulations - you've successfully fixed your Mini Delta belt defect or broken belt!

With this file you will be able to print MONOPRICE MINI DELTA BELT JOINER with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on MONOPRICE MINI DELTA BELT JOINER.