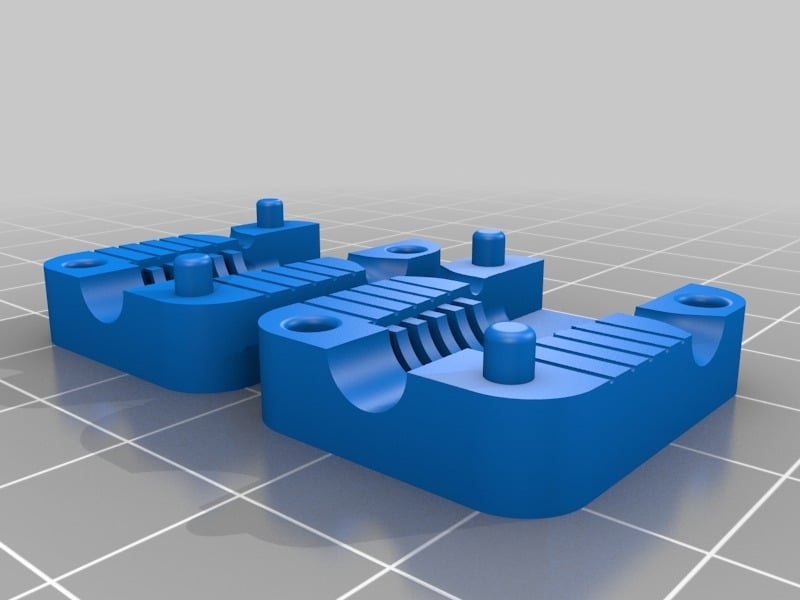

Mold for RJ45 plug V2

thingiverse

New version: streamlined and perfectly perpendicular. Enhanced CAD files now available. I apply a glue gun to craft insulation on the plug, making sure the hot-melt gun is thoroughly warmed up so I can squeeze out a sufficient amount of adhesive. In low-power models of the gun, continuous extrusion is not feasible. It's essential to remember that the lifespan of the melt is roughly one minute. The mold is printed from PET-G using a 0.4 nozzle and 0.1mm layer thickness. To ensure easy separation of the adhesive, the surface must be lubricated with a suitable substance. Recommended sequence: 1. Lubricate the mold 2. Preheat the gun for six minutes 3. Squeeze the glue from the side of the cable into each half of the mold 4. Connect the halves 5. Apply additional glue to fill the inner part of the plug and allow it to spill over onto the outside surface 6. Allow the mixture to cool for five minutes 7. Disassemble the halves and remove excess adhesive with a knife

With this file you will be able to print Mold for RJ45 plug V2 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Mold for RJ45 plug V2.