Modifications to QU-BD extruder for reliable ABS printing.

thingiverse

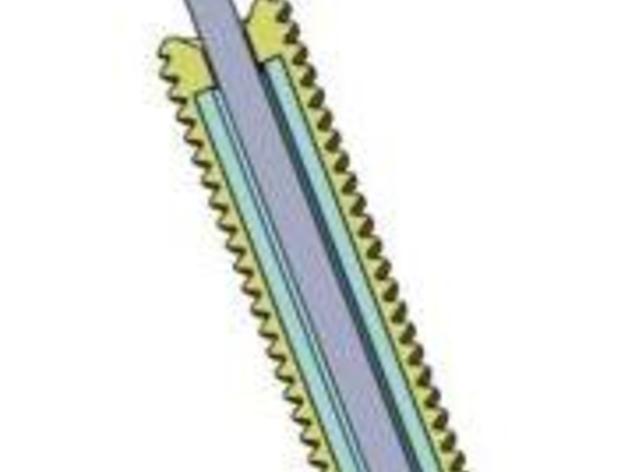

Initially, I encountered issues when printing ABS using a QU-BD extruder on my Hadron Ordbot. The problem occurred during large model prints with long run times, resulting in feed failures after a couple of hours. Research showed that this was a common issue with QU-BD-style print heads due to the top of the stainless steel feed tube overheating. To resolve this, I collaborated with a local machinist who created a new feed tube using high-temperature PTFE (Teflon) from McMaster Carr. This insulates the filament within the feed tube of the heater block. After running the modified head for over 100 hours, I dismantled it and found no signs of melted filament outside the melt chamber. As a result, I can now reliably print ABS for any size part and any duration. My printing settings include ABS at 235°C, a bed temperature of 110°C for the first layer and 100°C thereafter, with a glass bed covered in Clear Monokote and sprayed with AquaNet Super Hold hair spray. This setup ensures excellent adhesion and clean removal of parts from the print bed, while requiring minimal maintenance for the Monokote and hairspray surfaces.

With this file you will be able to print Modifications to QU-BD extruder for reliable ABS printing. with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Modifications to QU-BD extruder for reliable ABS printing..