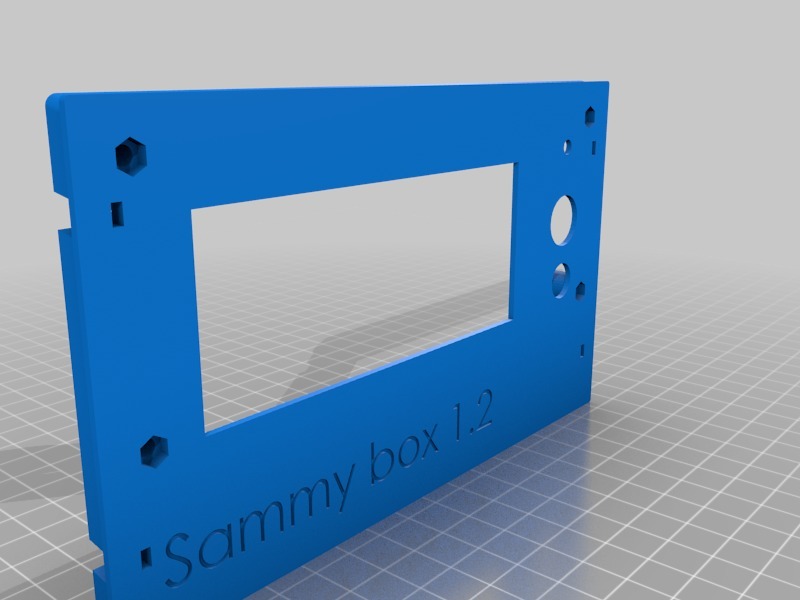

MKS Gen-L Case

thingiverse

Version 2.0 Update. After multiple prints of the design, I identified areas in need of improvement. Here's the list of changes: * The screen mounted in the cover has a 15-degree slant. Several interference points were found in the cover that made the fit challenging. The cover was re-designed to match the slanted case opening and eliminate all interference points. * All posts on the walls inside the case have been redesigned with a gradual build, eliminating the need for bridging by the printer. This should improve printing quality on less expensive printers prone to bridging issues. * STL files were regenerated to simplify geometry and decrease file size, resulting in faster slicer processing times without compromising precision. * A vanity change was made: the box's name (Sammy Box) is now only one layer deep (0.2), significantly improving print quality around the text. Version 1.3 Update: * General changes were made to reduce print time and filament usage, resulting in this version using half as much material as Version 1.0. * Increased hole tolerances to account for printer wobbling between layers. * Added missing cover mounting screw location, rectifying a mistake from Version 1.0 where the case was not fastened properly. * Lowered fan location to allow cooling under the MKS board and reduce box height. * Moved MOFSET mount closer to heating bed wires on the opposite wall. * Adjusted TL-Smoothers location for better alignment with X and Y axis plugs, moving extruder and Z-axis holes as well to enhance cable management. Version 1.0 of a case designed for FLSUN iPrusa printer but adaptable to any printer using 2020 rails (or 2040, 4040, etc). The case houses the following components: * MKS Gen-L controller board. * 1x 60x20mm fan. * 1x 60x10mm fan (optional). * 2x DC-DC adjustable PSU's (LM2596). * 1x Heated bed power module. * 2x TL-Smoothers modules. * 1x RepRap Discount LCD. When designing the case, I had several requirements: * The case should be mountable on a 2020 rail system. * All parts should be printable on a small 200x200 printer bed. * Components should be mounted with nuts instead of screwing into plastic. * The case should have no protrusions like bolt heads. * Larger fans running at lower speeds should maintain quiet operation while providing adequate cooling. * Air cooling direction change should be avoided to maintain effective cooling (no top fan with side exhausts). * The case should be able to hold all printer components. For this project, I chose a 60mm fan for two reasons: * A single 40mm fan does not move enough air to cool all equipment, especially when running stepper drivers like 2208 that generate a lot of heat. Running two 40mm fans at max speed makes things loud, but a 60mm fan moves three times the air of a 40mm fan and can be run at 60% its speed while still pushing as much air as two 40mm fans. * With all components mounted in the case, there was no way to maintain clearance without making the case deep. After all components fit into the case, I realized that there would be room for a 60mm fan. Here's the list of components bought to fit into the case: * MKS Gen L 1.0 controller: https://www.amazon.com/dp/B07BFSMTPS * DC-DC voltage regulators: https://www.amazon.com/dp/B01GJ0SC2C * Printer bed controller: https://www.amazon.com/dp/B01HEQVQAK * TL-Smoothers: https://www.amazon.com/dp/B071WG3SZQ * 60x20mm Fan: https://www.amazon.com/dp/B00ZS9P9IG Keep in mind, the fan listed is 24V since I'm using a 24V power supply. When ordering, you can use any voltage fan since you will have a DC-DC regulator next to the fan. Also, before printing, make sure to rotate the part so that the case opening faces up.

With this file you will be able to print MKS Gen-L Case with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on MKS Gen-L Case.