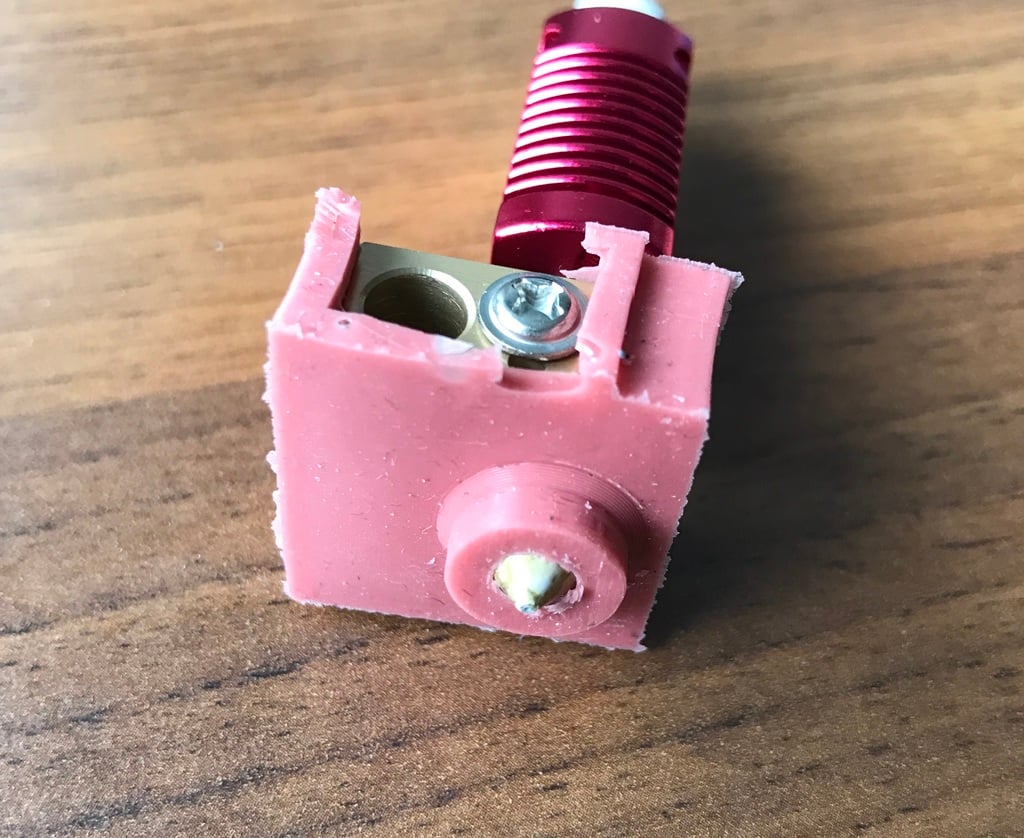

MK8 heatblock sock mold

thingiverse

The Ultimate Guide to Crafting Your Own Nozzle Socks with High-Temperature Silicone Get ready to take your 3D printing skills to the next level by creating your own nozzle socks using high-temperature silicone. This ingenious mold design consists of five interconnected parts, carefully crafted to ensure seamless printing of polycarbonate. A Thin Spacer Takes Center Stage The slender section of this mold serves as a vital spacer, expertly bridging the gap between the inner and outer components. Its precision-engineered design ensures that your prints emerge with exceptional quality and consistency. Heating Up: A Challenge Overcome When using high-temperature silicone, achieving optimal heat control is crucial. To overcome potential temperature fluctuations, I deliberately covered as much of the heatblock as possible. Although this step was essential, it introduced an unexpected challenge – a 7°C overshoot during heating up. However, recalibrating the PID helped to rectify this issue. A Slick Solution for Silicone Filling Filling high-temperature silicone through the small hole can be a messy affair. To streamline this process, I recommend assembling the mold first, leaving out only the top part. Next, fill the mold with a generous amount of silicone, then screw everything together before topping it off with the remaining silicone. For inspiration and guidance, I turned to the expert source: https://a360.co/2w8UWjo

With this file you will be able to print MK8 heatblock sock mold with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on MK8 heatblock sock mold.