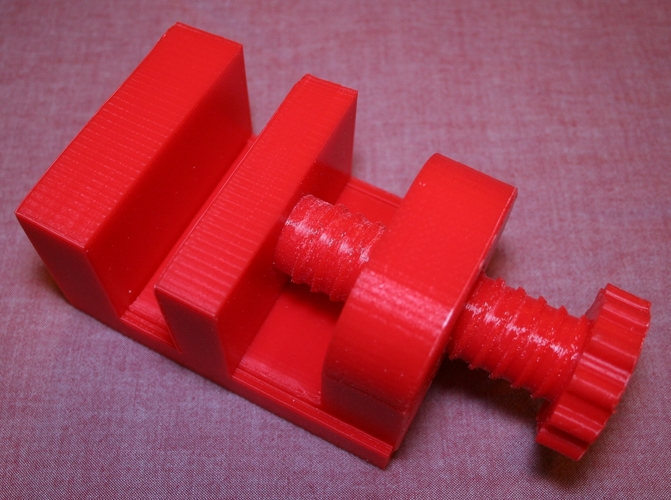

miniVice2

pinshape

I required a compact vice to secure items in place when soldering and gluing materials. This is my initial prototype, as evident from my 3D printed components, which have been modified to enhance their functionality. Assemble the two bases by attaching them with the two 10mm pins. When printing the "ScrewEND" part, ensure the larger hole faces downwards for a flat clamping surface at the end of the print. The internal rats nest within the 25mm bore simplifies gluing the 3mm metal screw into the large plastic vice screw. I remove excess adhesive from the end of the plastic screw after inserting Gorilla Glue to prevent it from bonding with the end block, allowing for smooth rotation of the metal screw while opening and closing the vice. To initiate threading, I used a pair of pliers initially; the reason is unclear, but once started, the process worked smoothly. A tiny drop of oil or lubricant may further facilitate rotations, potentially making the vice even more efficient.

With this file you will be able to print miniVice2 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on miniVice2.