miniCore - Cartesian 3D printer KISS principle

thingiverse

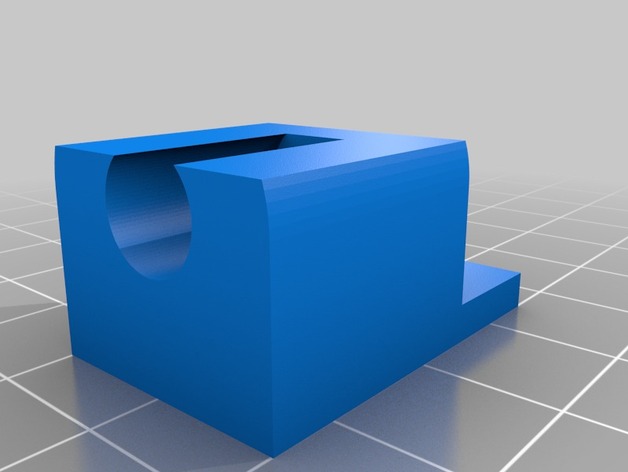

I wanted to create a cartesian printer with minimal footprint in relation to the available print bed, targeting 300x300 outer dimensions to print on 215x215 borosilicate glass I have around. The extrusion is based on RichRap's fantastic Sli3dr concept, which was my basic inspiration. After some initial parts, I reverted to the KISS principle, where each part provides one function only. GT2 belts are on separate levels and do not cross over. 608 bearings can be found in your children's skates, and fit perfectly on the holders without screws. Regular updates will be provided as the project progresses. Level One First publish of rod holders Z escalator parts Front bearing mounts BOM: Z Escalator: 1 x 400mm 8mm trapezoid lead screw (I use TR8x1.5 with 2133.33 steps/mm) 1 x 8mm trapezoid nut TR8x1.5 17x15mm 2 x 450mm, 8mm sliding rods 2 x LM8UU or RJ4JP-01-08 XY: 2 x GT2 timing belts (those from Kossel Mini build work perfectly) 8 x 608 bearings 2 x 290mm 8mm rod for X 2 x 250mm 8mm rod for Y 4 x LM8UU / Igus RJ4JP-01-08 Find it on github: https://github.com/gweber/minicore Print Settings: Printer Brand: RepRap Printer: 3DRAG Rafts: Yes Supports: Yes Resolution: 0.3 Infill: 25% Notes: Support only needed on y-carriage.

With this file you will be able to print miniCore - Cartesian 3D printer KISS principle with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on miniCore - Cartesian 3D printer KISS principle.