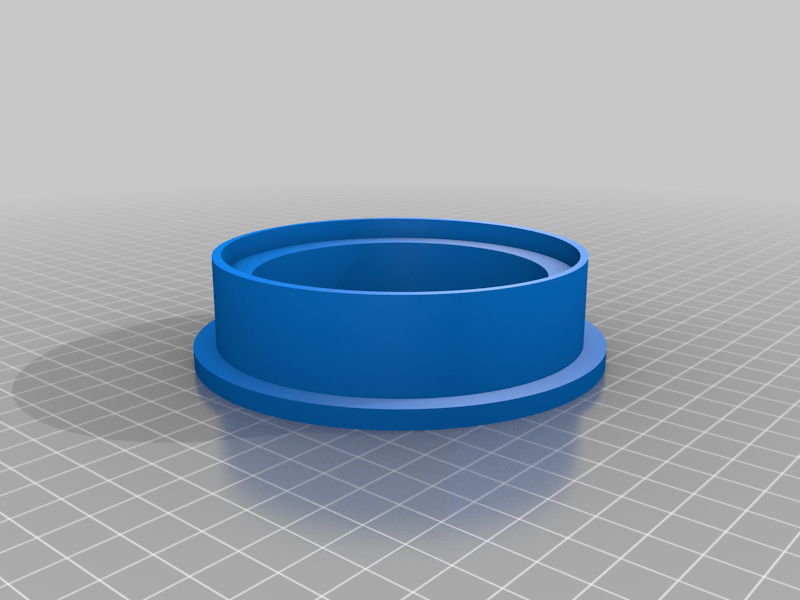

Mini Press Shell Holder

thingiverse

Printed in steel powder and infused with bronze. The material is very strong and used black coloring and then polished. With Steel 3D Printing, your part is created by binding together layers of steel powder. After a layer of steel powder is spread across the base of a “build box”, a special print head moves back and forth over the layer, and deposits binding agent at specific points, as directed by a computer and your design file. Once the layer is finished and it has been dried with powerful overhead heaters, a new layer of powder is spread, and the process begins again. In this way, layer by layer, from the bottom up, your part is created. (iMaterialize) Part fits a Vigor SS-140 Japanese eyeglass tabletop mini press. Useful for centering and holding cases in press to allow for safe and effective primer removal and collection. Ram stroke is limited as travel is about one inch so only smaller cases will fit.

With this file you will be able to print Mini Press Shell Holder with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Mini Press Shell Holder.