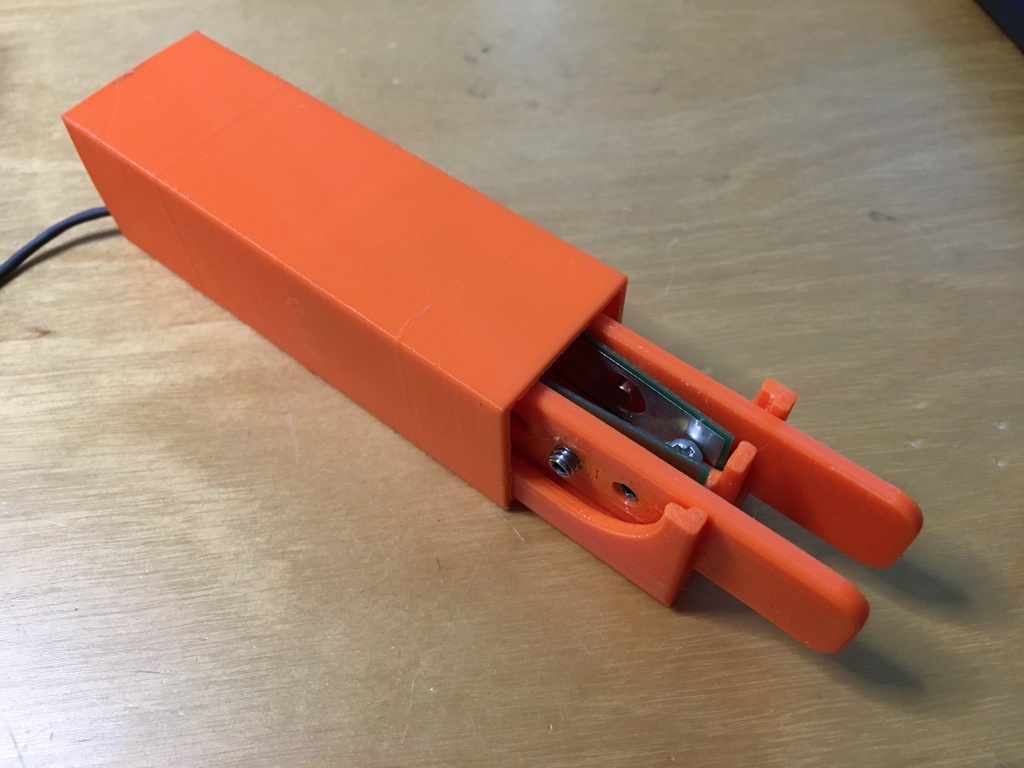

Mini morse paddle

thingiverse

Human: I'm inspired by http://members.ziggo.nl/cmulder/paddle.htm and http://www.palm-radio.de. This project is still in development, but the current version (V2) works well. You can see it in use at https://youtu.be/1xGeypPl-cU. To make this paddle work, you'll need some specific hardware: * 6 x M4x4mm set screws (available at McMaster-Carr: https://www.mcmaster.com/92605a110) * 4 x M2.5x5mm phillips head screw (available at McMaster-Carr: https://www.mcmaster.com/92000a103) * 2 x M2.5x12mm phillips head screw (available at McMaster-Carr: https://www.mcmaster.com/92000a107) * 6 x M2.5 nut (available at McMaster-Carr: https://www.mcmaster.com/91828a113) * 1 x ball plunger 5mmx6mm (available on Amazon: http://a.co/d/gtlAK51) * Thin headphone wire (2mm) - for example, you can use Mogami ultraflexible miniature microphone cable (available at Markertek: https://www.markertek.com/product/2490/mogami-w2490-ultraflexible-miniature-microphone-cable-gray-per-foot) For adjusting the resistance: * 1/8x1/8 N52 magnets (available at K&J Magnetics: https://www.kjmagnetics.com/proddetail.asp?prod=D22-N52) * Or, you can use 1/8x1/16 N52 magnets (available at K&J Magnetics: https://www.kjmagnetics.com/proddetail.asp?prod=D21B-N52) * Alternatively, you can use a spring with a 3mm or 1/8 OD. **Note:** Depending on the material used, the center post may flex. This is happening with PETG. I'm looking at options to make that section rigid. If you have any suggestions, please let me know! Recent updates: * 11/17/2018: First test with PCB 1/32" as the springboard. This is a bit stiff - around 50g to squeeze the paddle. Next test will be with some brass strips, and then 3d printed springboard with some copper shim glued on top to make the contacts. * 11/28/2018: Uploaded V2: Ordered 0.6mm PCB from JLCPCB and got around 10g for 3mm of travel. 0.4mm PCB is available, but as a much more expensive option for small runs. Based on some research (https://www.qsl.net/ik6bak/dynamometer.html), it seems that users want from 5 to 50g. This all depends on the travel. To get to 20g, this means a spring rate of 0.37lb/in and to get to 50g, we would need a preload of ~7.5mm, or a different spring rate. The paddles are 3mm thick - this may be possible. * 12/07/2018: Uploaded case with holes for the ball plunger. Updated description * 12/08/2018: Uploaded dimensional drawing for the springboard * 12/18/2018: Replaced the STL file for the paddle base as user notified me that some holes were missing. * 01/06/2019: Released version 3, with a 3.5mm connector, and a much more flexible paddle using a printed flex section.

With this file you will be able to print Mini morse paddle with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Mini morse paddle .