Mini Lathe 3" Chuck Jaws Holder for grinding service.

thingiverse

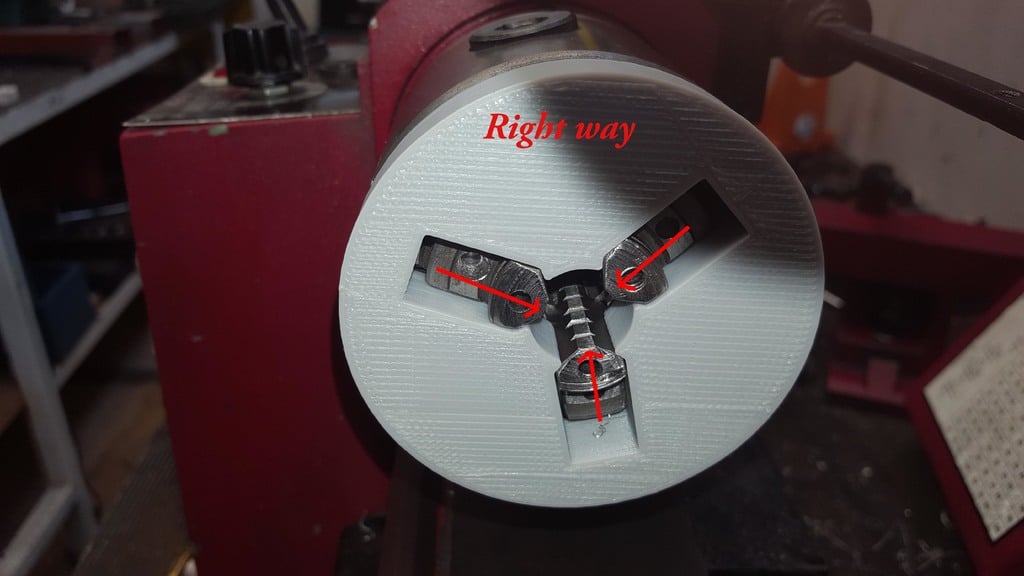

I recently followed a video's instructions to modify my mini lathe's chuck, which had a runout of around two thousandths. The video suggested using an outer ring to hold the jaws in place and create a makeshift grinder service. Unfortunately, the outcome was far from ideal. Instead of resolving the issue, the modification increased the runout to 10 thousandths. This was not what I had hoped for, especially considering the amount of time and effort I invested in the project. The main problem lies in the design of my lathe's jaws, which have a slight amount of play. As a result, an external grip would only exacerbate the issue. A more effective solution would be to incorporate a grip that is naturally aligned towards the center of the chuck. In search of a solution, I stumbled upon an old video featuring a gentleman from the 1940s who had designed a system to address this very problem. Inspired by his ingenuity, I decided to create and print a custom part for my mini lathe. With some trial and error, I was finally able to rectify the situation and restore my chuck to its former glory. In sharing my experience, I hope to prevent others from making the same mistakes I did. Warning: If your 3D printer is not precisely calibrated, do not attempt this project. Proceed at your own risk.

With this file you will be able to print Mini Lathe 3" Chuck Jaws Holder for grinding service. with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Mini Lathe 3" Chuck Jaws Holder for grinding service..