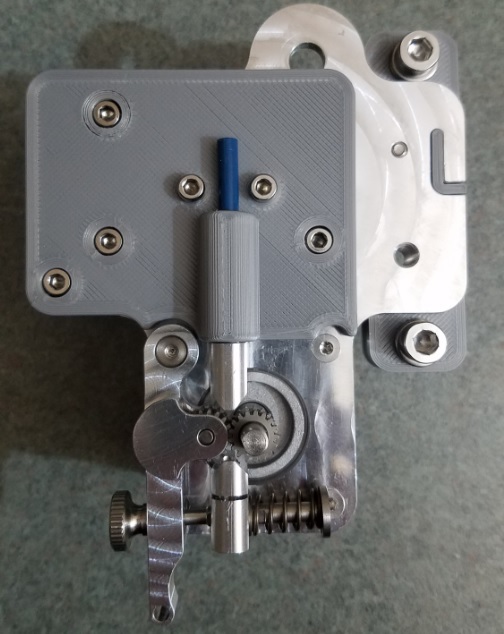

Micro Swiss Ender 5 Direct Drive to Bowden Extruder Adapter

thingiverse

Can a Micro Swiss Ender 5 Direct Drive system be converted to a bowden extruder? I made a couple brackets to find out... I was curious to see if a Micro Swiss direct drive system for the Ender 5 could be converted into a Bowden Extruder (without modifying the Micro Swiss bracket in case I want to go back to direct drive). I created a mounting adapter in Fusion 360 that will allow the Micro Swiss aluminum direct drive plate to mount to the 2020 rail on an Ender 5 similar to the original Ender 5 extruder to give it a try. I then created a Capricorn tube holder bracket to hold the bowden tube. Once the tube holder bracket is printed with support, pop out the support and then use a 5/32 drill bit to remove excess material. It will be tight so then step up to a 3/16. I turned the bits by hand to clean up the tube hole. The tube will lay flat against the bracket. The bowden tube bracket is held on to the Micro Swiss aluminum bracket with four recessed m3x8 screws and holes closest to the tube are m3x12 screws. I haven't tested the Micro Swiss extruder in the Bowden configuration yet but the rail mounting adapter fits nicely over the contours of the Micro Swiss bracket. The mounting adapter slides over the wheel spacer post on the Micro Swiss Ender 5 direct drive plate and also slides into the belt slot and is secured to the Micro Swiss Ender 5 bracket with an M3x6 screw which is recessed into the back (you may want to print it with support for the M3 screw hole). I had two M5x16 screws with T nuts which are a little long so I added two M5 washers under each M5 screw which will work. When you tighten the Capricorn tube holder bracket down, put a tube in it to help keep the tube holes aligned. The Micro Swiss extruder I know will spin backwards with the original Ender 5 extruder cable and default firmware but the extension cable that comes with the Micro Swiss direct drive system will also reverse the motor rotation as well so I will just use the extension cable in order to reverse the motor direction to test. I believe it is also possible to pin swap a couple pins in the original cable to not need the stepper extension cable or alternatively make a change to the Marlin firmware as well to change the extruder direction of rotation. I know that the e-steps will need to be adjusted. If I recall the change is roughly from a value around 97 to around 138 also. The next step is to test. I have printed and assembled but have not yet tested this. I included the stl, step file, and Fusion 360 files for both brackets. Enjoy. Update: I stumbled onto a model for the Micro Swiss Ender 5 direct drive bracket so I was able to check the fitment of my brackets including the areas I could not see once assembled. I learned about this a little late as my parts were designed by measuring a real Micro Swiss bracket with a digital caliper. Designing would have been easier with the model but at least I can check how I did for fitment after the fact. I included a screenshot of the alignment check using this model. My brackets could be improved a little bit but not too bad as they are...

With this file you will be able to print Micro Swiss Ender 5 Direct Drive to Bowden Extruder Adapter with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Micro Swiss Ender 5 Direct Drive to Bowden Extruder Adapter.