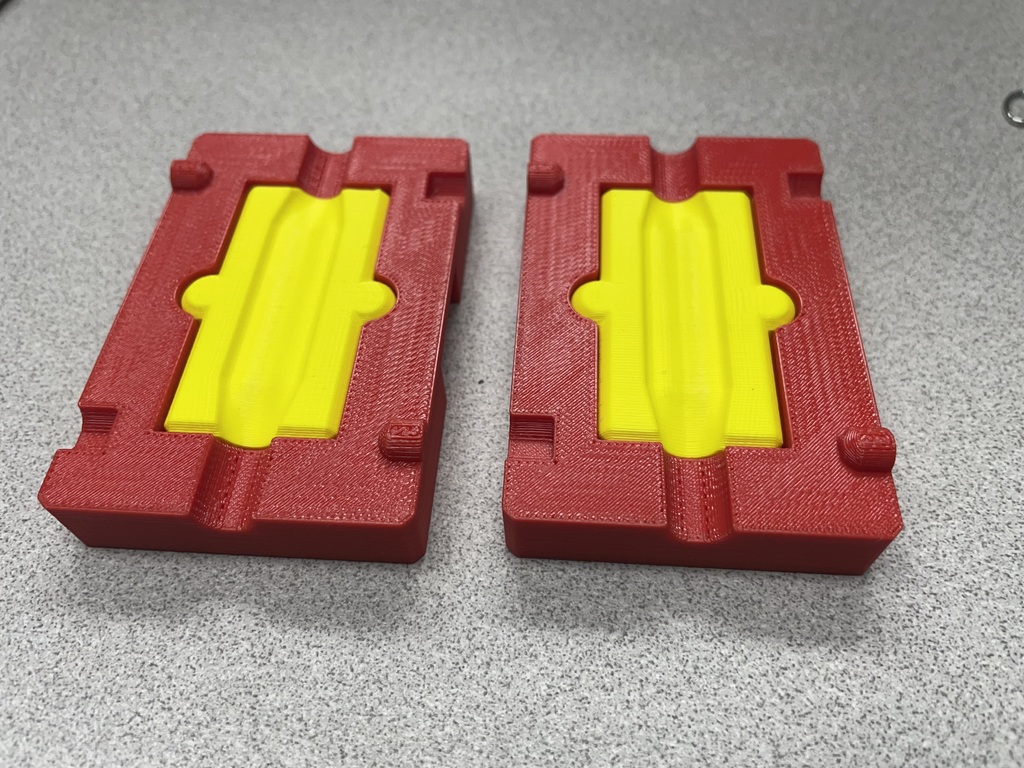

Metal Tubing Flattener

thingiverse

I designed these parts to flatten some 5/16 stainless tubing with a 0.028" wall thickness to create an air nozzle shape desired by my coworkers. If the tubing is pressed with two flat plates, it will cause the tubing to deform unevenly and collapse the center. These die plates incorporate a small groove down the center to support and evenly distribute the pressing force. By sliding stock tube all the way through the die, the flattened section is supported by the nondeformed sections on either side making for an even deformation without buckling the very end of the tubing. I suggest printing the die plates standing upright with supports and place the seam on the back to give the inside of the plates a smooth even finish. The higher the infill percentage on the die plates, the better. To use this tool, simply place 5/16 tubing through the holes in the outer die guides and clamp the sides with small binder clips. Next, sandwich the die plates on either side of the tubing and position in a bench vice. Use the vice to evenly press in the die plates until the back faces are flush with the faces of the guides. This should result in a tube with a ~11mm wide flattened section. This design could be easily altered for other diameters/flattened thicknesses. Printed in ABS on Stratasys Fortus 250mc

With this file you will be able to print Metal Tubing Flattener with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Metal Tubing Flattener.