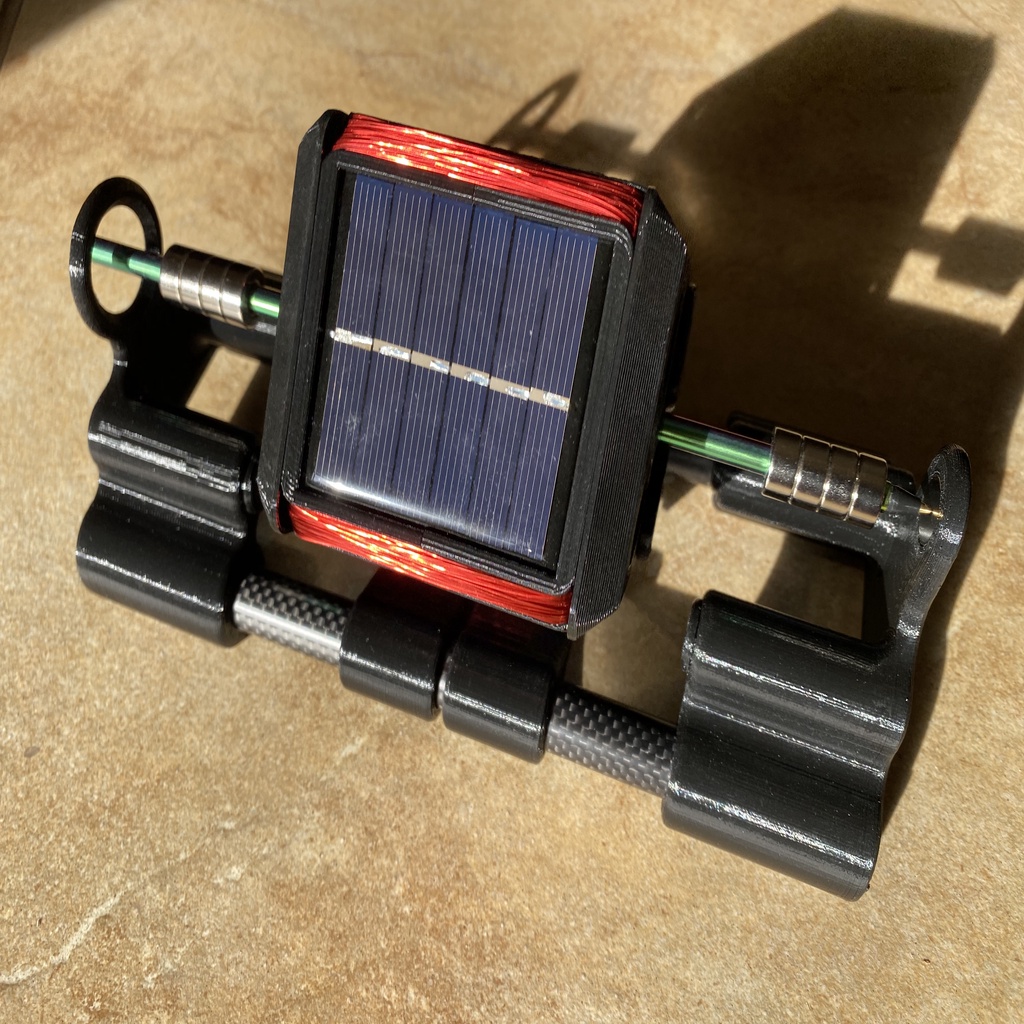

Mendocino Motor

thingiverse

UPDATE - Added a zip file of printable weights (Weights.zip) to use in balancing the rotor by snapping them into the holes in the "HolyRotorCaps". These weights can also be used to give a little extra flair to a balanced rotor. When completed and sitting in the magnetic field wells, the rotor as designed isn't especially easy to balance. To begin with, wind the rotor with the shaft in and the little ferrules in place. 100 turns of 28 AWG magnet wire are needed. Winding goes like this: first on one side of the shaft, then on the other side, and finally back again. The ferrules protect the windings if/when you pull the rotor shaft out and reinsert it, and they also act as a height gauge to keep from piling the wire too high since the end caps meet the tops of them. A nice wiring diagram and theory of operation are available at https://www.kjmagnetics.com/blog.asp?p=mendocino-motor-1 and https://www.kjmagnetics.com/blog.asp?p=mendocino-motor-2 The thrust bearing is the head of a Bic ball point pen. The ball is a very hard sphere and has very low friction against the D801-N52 disk. Use a couple of pieces of thin-wall heat shrink tubing to make the pen tip a tight fit in the rotor shaft. It doesn't need to be super tight, though, since forces are low. The plastic parts and rails fit with no glue necessary yet are tight enough to hold assembly as printed on my printer. The only support used was when printing the field magnet rails since they have those pockets. To get good circles, all parts with tubes are printed with the tube axes oriented vertically in the printer height axis as in the grayscale grab from MakerBot Print. I used double stick tape for the field magnets and a small drop of super glue on the thrust magnet. All levitation magnets and the thrust magnet have their poles oriented the same direction. That levitates the rotor, and with the ring magnets in the rotor locations shown and the levitation magnets in the base pushed all the way to the stops, pushes the pen ball back against the thrust magnet. Magnet locations are fairly important to get this to work properly. Push the levitation magnets in the base all the way in and glue if you need to to hold them in position. Try to get the levitation magnets on the rotor shaft the same as depicted. The stainless steel straw I used as the rotor is 8.5" long so rotor magnet dimensions are relative to that. The field magnets are also all oriented their own same way and it looks like their polarity sets the direction of rotation. Balance the rotor and enjoy!

With this file you will be able to print Mendocino Motor with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Mendocino Motor.