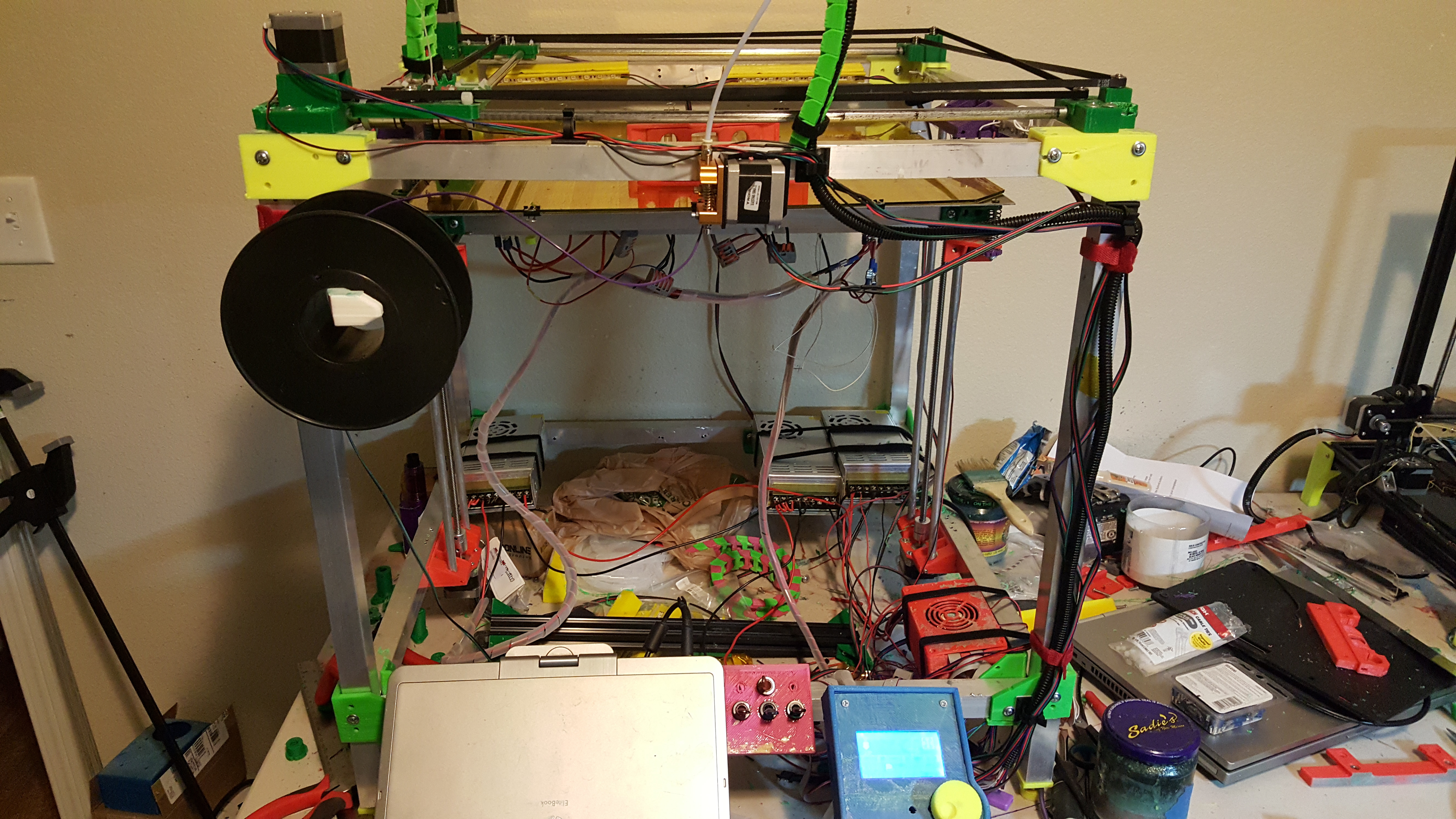

MegaTronXY CoreXY

myminifactory

Hello everyone, I've successfully converted my MegaTronXY X1 into a CoreXY Printer with an impressive printing area of 400x450x370. After learning about the remarkable speed of CoreXY printers, I decided to give it a try and upgrade my machine. So, I took apart my MegaTronXY X1 printer frame and transformed it into a CoreXY setup. The Ramps full Graphic Display 12864 Case and Mount can be found here: https://www.thingiverse.com/thing:1343964 - any Ramps1.4 case will work, as I wanted to utilize the Graphics display for easy adjustments. I've got three types of Anti-wobble inserts that prevent any wobbling issues. You can either drill out the Z_stage_carriage_100mm v2 or edit it to include the anti-wobble inserts in the carriage platform - I simply drilled it out and glued it in place after leveling the carriage. This conversion utilizes the same frame mounts found on my MegaTronXY X1, along with parts and supplies from Lowes and Home Depot. You can build this using either 3/4 aluminum square tubing or 1-inch square tubing; the frame mounts are scalable - just resize for 3/4 tubing. Additionally, you can use 3/8 aluminum rods from Home Depot and Lowes, which may be slightly smaller but work perfectly fine. You can check out my MegaTronXY X1 here: https://www.thingiverse.com/thing:2326560 to see the tubing mounts in action, and I borrowed the X and Y stepper mounts from here: https://www.thingiverse.com/thing:1849704 - I've made some modifications to the Z-axis bed support, ensuring there's no wobbling at all. I've also added level springs and screws for easy bed leveling; I haven't needed an auto-level install since I can adjust the bed as needed. Everything was crafted from 3/4 square tubing or 1-inch square tubing, which you can easily find at Home Depot or Lowes. The heatbed consists of four 120-watt MK heat plates glued on using Fireplace caulk (available at Home Depot or Lowes); screws were used for secure attachment - 3/4 and 1-inch self-drilling metal screws to be exact. This model utilizes three 400-watt power supplies, with two powering the heatbed connected to the Ramps 1.4 board via 12-volt automotive relays rated at 60 amps each at 14.4 vdc - these relays have their own fans for cooling purposes. The third power supply runs the extruder and motors along with LED lights illuminating the bed. Heating the bed doesn't take long; I've also noticed that the relays keep themselves cool. On a side note, the Bed Z Motors are wired together in series to ensure even raising and lowering of the bed.

With this file you will be able to print MegaTronXY CoreXY with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on MegaTronXY CoreXY.