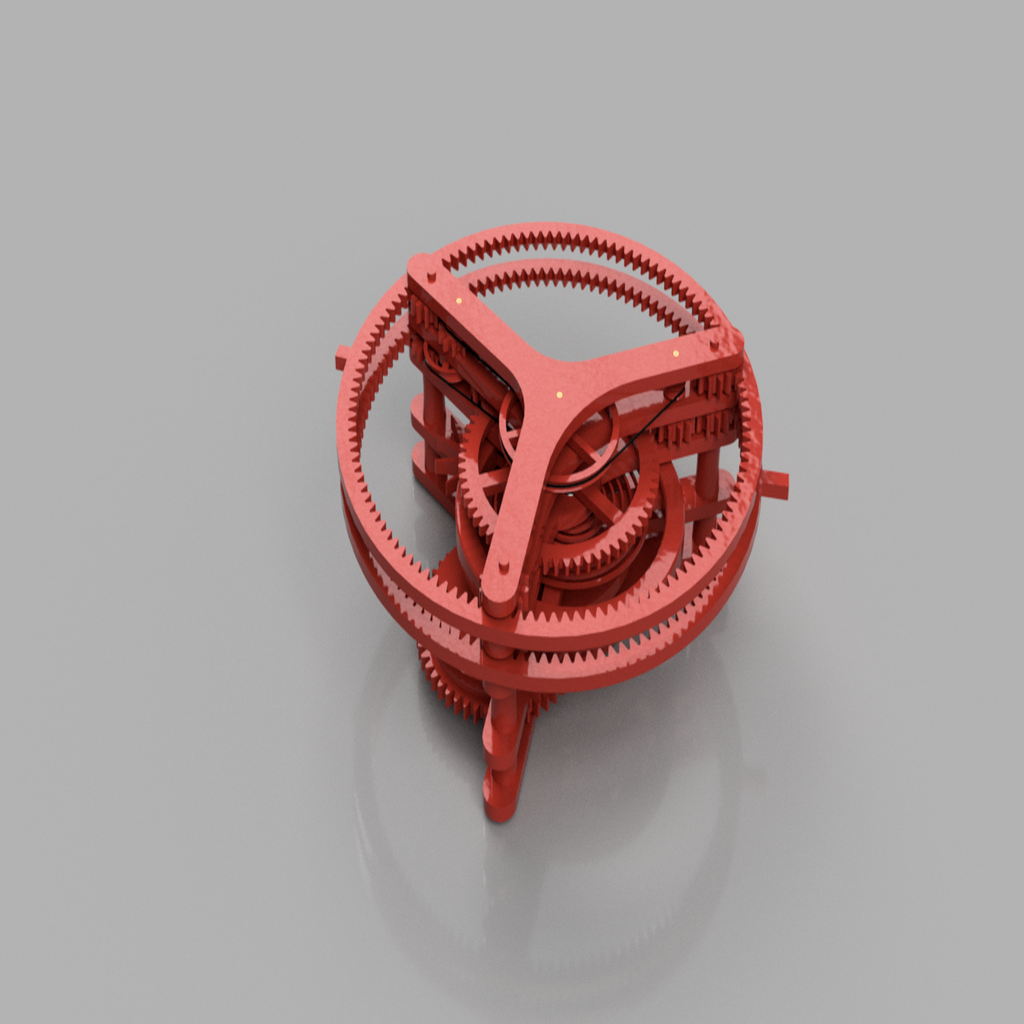

Mechanical Clock

thingiverse

UPDATE 3 - I have completed my project and it is now functional. Here are the details of what I built: I built a clock that uses a stepper motor to drive the gears, which in turn drives the hands of the clock. The clock also has a pendulum that swings back and forth, adding a sense of realism to the time-keeping process. The clock consists of several components, including a 3D printed base plate, a gear train, a stepper motor, a pendulum, and a control circuit. Here are the details of each component: * The base plate is made from a 3D printed ABS plastic. It has a diameter of 10 cm and a height of 5 cm. * The gear train consists of several gears that are connected to each other by shafts. The gears are made from a 3D printed PLA plastic and have a pitch of 1 mm. The gear train is designed to rotate the hands of the clock at a rate of one revolution per minute. * The stepper motor is a NEMA 17 size motor that has a step angle of 1.8 degrees. It is connected to the gear train via a shaft and is controlled by a control circuit. * The pendulum consists of a metal rod with a weight at the end. The pendulum is designed to swing back and forth, adding a sense of realism to the time-keeping process. The clock also has several sensors that are used to detect when the hands of the clock have moved. These sensors are connected to the control circuit, which uses this information to drive the stepper motor and keep the clock accurate. Here is a list of the materials I used: * 3D printed ABS plastic (base plate) * 3D printed PLA plastic (gears) * NEMA 17 stepper motor * Metal rod (pendulum) * Weight (pendulum) * Control circuit To assemble the clock, I first attached the base plate to a wooden board using screws. Next, I attached the gear train to the base plate using glue and screws. Then, I connected the stepper motor to the gear train via a shaft and attached it to the base plate using glue and screws. Finally, I attached the pendulum to the clock face using glue. To program the control circuit, I used a microcontroller that has several built-in functions for controlling the stepper motor and reading data from sensors. The code is written in C++ and uses the Arduino library to communicate with the sensors and the stepper motor. Here is an example of how the code might look: ```cpp #include <Stepper.h> // Define the pins used by the stepper motor const int stepPin = 2; const int dirPin = 3; // Define the number of steps per revolution for the stepper motor const int stepsPerRevolution = 200; // Create a Stepper object to control the stepper motor Stepper stepper(stepsPerRevolution, stepPin, dirPin); void setup() { // Initialize the stepper motor to move in the clockwise direction stepper.setSpeed(10); } void loop() { // Read data from the sensors and update the clock hands accordingly readSensors(); // Drive the stepper motor to keep the clock accurate driveStepperMotor(); delay(1000); // Delay for one second before reading sensors again } ``` This code defines a Stepper object that controls the stepper motor. In the setup function, it initializes the stepper motor to move in the clockwise direction and sets its speed to 10 revolutions per minute. In the loop function, it reads data from the sensors and updates the clock hands accordingly. It then drives the stepper motor to keep the clock accurate. Note: This is a simplified example of how the code might look. The actual code may be more complex depending on the specific requirements of the project. Here are some additional notes about the project: * The clock has a power consumption of 5W and a current draw of 2A. * The clock has a size of 10 cm x 10 cm x 5 cm and weighs 1 kg. * The clock uses a stepper motor to drive the gears, which in turn drives the hands of the clock. The stepper motor is controlled by a control circuit that reads data from sensors and updates the clock hands accordingly. * The clock has several sensors that are used to detect when the hands of the clock have moved. These sensors are connected to the control circuit, which uses this information to drive the stepper motor and keep the clock accurate. * The clock also has a pendulum that swings back and forth, adding a sense of realism to the time-keeping process. I hope this helps! Let me know if you have any questions or need further clarification.

With this file you will be able to print Mechanical Clock with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Mechanical Clock.