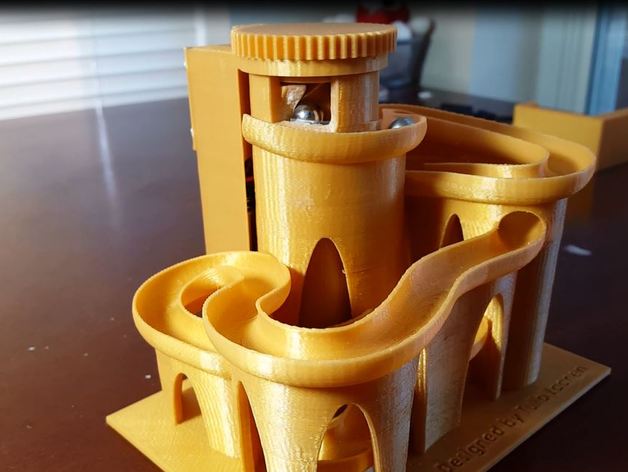

Marble Machine 2 - Repaired motorized variant

thingiverse

The lift screw was fixed, its original direction causing marbles to fail in climbing the lift. Chrome steel balls of 3/8 inch were used, easily found at affordable prices on eBay. Lessons Learned: Use a floor fan to boost cooling for the lift screw; warped edges can result from inadequate cooling. Smoother lift operation ensues with optimal cooling. Add a small strip of plastic at the top of the lift for marbles to flip over, preventing them from getting stuck. A photo illustrates this solution. This prevents lengthy waits for another marble to push the first one over. Similarly, add a small strip of plastic at the bottom of the lift to cover the rough surface of PLA and facilitate smooth marble entry into the lift. Without it, marbles must be manually nudged or hit by an incoming marble to enter the lift. The cylindrical component at the base of the lift is crucial; if damaged, reprint and secure with superglue for continued operation. Superglue was applied to the gear connecting to the motor due to a lack of patience for installing a set screw. Print Settings: Printer: Monoprice Select Rafts: None Supports: None Resolution: 0.2mm Infill: 20%

With this file you will be able to print Marble Machine 2 - Repaired motorized variant with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Marble Machine 2 - Repaired motorized variant.