M35A2 reinforced transmission shaft solutions

thingiverse

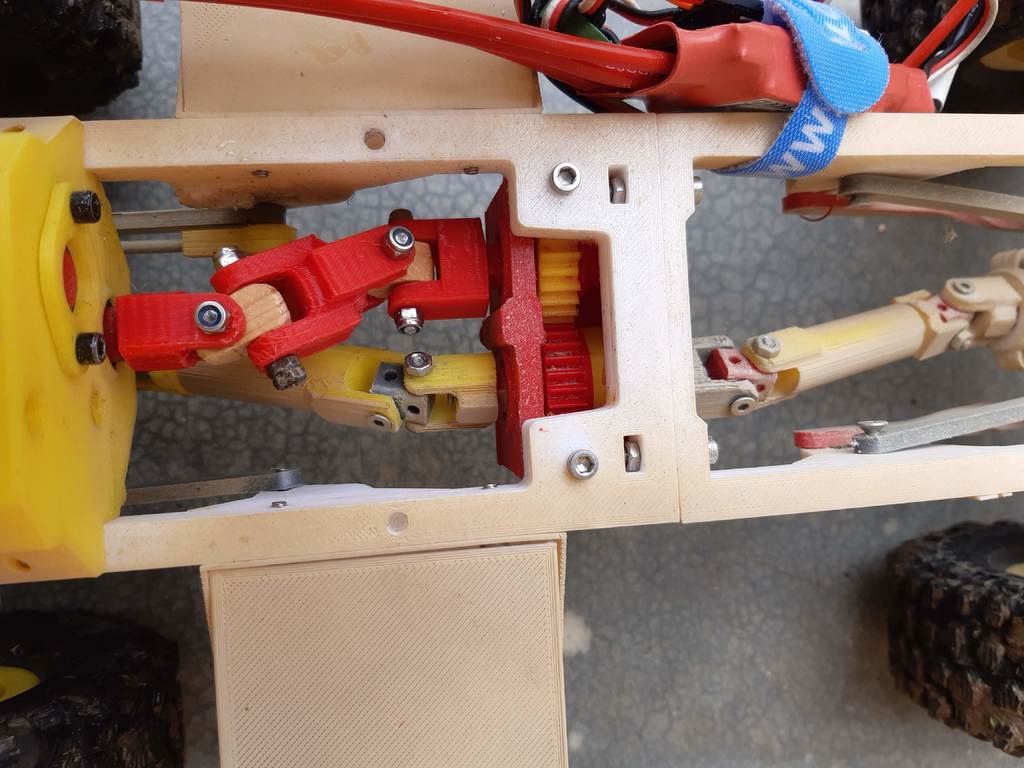

After numerous attempts to overcome the shortcomings of traditional transmission components, I've finally developed a design that works exceptionally well for me in soft off-road conditions. However, it's essential to note that this setup hasn't been thoroughly tested under harsh usage like a crawler would experience, as it still has limitations due to its plastic construction. To address some key issues, I've implemented the following modifications: 1. Double Square Joint: This design allows for two full screws crossing the shaft, significantly improving torque levels. Unfortunately, my initial tests with PLA resulted in a breakage within minutes. Fortunately, using wood as a material has proven successful so far, but aluminum would be the ideal choice. 2. Printing Shafts Horizontally: By printing the shafts in this orientation, they become stronger and more durable (100% fill recommended). 3. Using Reinforced U Joint: This modification also enhances strength when combined with horizontal printing. 4. Central Differential Ratio Change: This update will be shared soon for all to benefit from. 5. Removing Differential Front/Rear and Central: The existing gears are too small and prone to quick wear in off-road conditions, making this upgrade necessary. To see the design in action, please visit the following videos: https://youtu.be/UJJZdykP2GI https://youtu.be/rvvbTu28COc Enjoy!

With this file you will be able to print M35A2 reinforced transmission shaft solutions with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on M35A2 reinforced transmission shaft solutions.