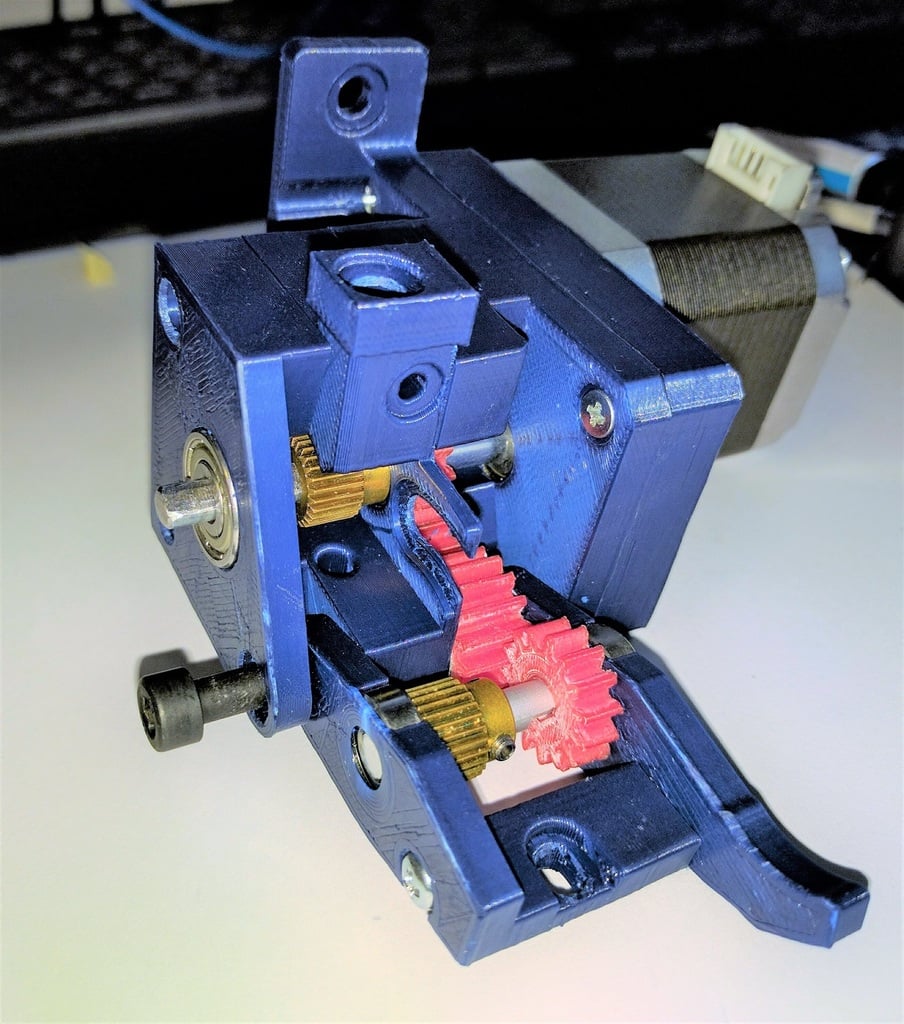

Lotar's Dual Gear Extruder

thingiverse

This is a reinvented extruder born of necessity. I spent hundreds of hours with mostly successful printing using a simple, direct drive extruder featuring a brass Mendel style gear. However, I encountered difficulties when using a small nozzle (0.2 mm), as the extruder struggled to push the filament. To address this issue, I decided to replace the filament tensioner bearing and add another pusher gear to ensure that the filament would be pushed from both sides, minimizing grinding. Due to limited bearing options available to me, I transitioned from Mendel gears to brass mk10 (clone) gears. This is my 4th iteration of this project, and it's now easier to build and assemble than its predecessors. So far, the extruder has performed reliably for 30 print hours, but further testing is still required. This project is ongoing, and I'm confident that it will continue to improve with time. Throughout this process, I've learned how to design gears (Pitch Diameter, Pressure Angle, etc.). The internet offers an incredible wealth of knowledge, making it impossible not to learn something new if you're willing to put in the effort. After three iterations, I realized that I'm not alone in attempting a dual gear extruder. While others have approached this problem before me, my design is smaller and, hopefully, better than theirs. The extruder features a second gear that works counter-clockwise in synchronization with the main gear. To achieve this, I employed gears instead of belts or clockwork mechanisms. The clockwork system is separate from the extruder itself to prevent filament shavings from entering between the gears. For added power and accuracy, I incorporated a 3:1 reduction gearbox. Rather than creating new herringbone gears, I repurposed existing ones from the NSTT Extruder by Paciente8159. Part list: * 3 x M3 x 30 mm screws * 2 x M3 x 20 mm screws * 2 x M3 x 8 mm screws * 1 x M3 x 16 screw * 1 x M5 x 60 mm screw (internal hex head) - preferably with partial thread * 2 x M5 x 100 mm screws (to be cut for axles) - preferably with partial thread * 1 x M5 nylon captive nut * 4 x M3 nuts * Some washers * 6 x 695ZZ bearings (5x13x4) * 2 x 625zz bearings (5x16x5) https://youtu.be/sLyT0wXdCTk

With this file you will be able to print Lotar's Dual Gear Extruder with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Lotar's Dual Gear Extruder.