Longer LK4 LK2 / Alfawise U20 U30, Auto Bed Leveling - Nozzle Based

thingiverse

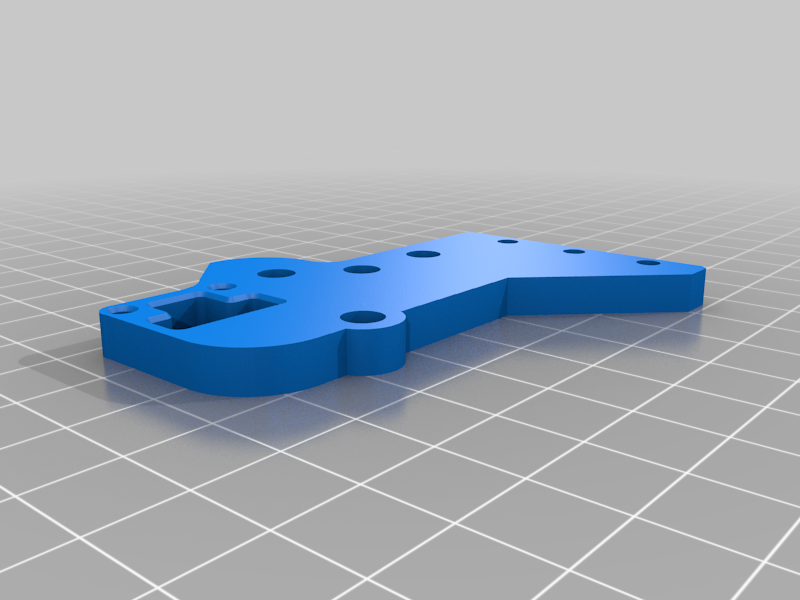

This is a remix of https://www.thingiverse.com/thing:4426518 The original design was created by Teaching Tech. Update 3/18/2021: I've abandoned using this on my own printer. Instead, I'm using a BL Touch device along with the stock fan shroud. However, I'm leaving this "Thing" up in case anyone still wants to use it. Update 8/3/2020: A 2nd version of the base plate was uploaded. This is slightly thicker (by about a millimeter) and it allows for more support by threading one of the x-carriage wheel bolts through the base plate. I was noticing that the prior base plate was flexing a bit, and this was designed to combat that. Also, the increased thickness provides a little bit of clearance between the original mounting threads for the hot end and the heads of the bolts securing the hot end to the shroud. The parts fit my Longer LK4 printer. I believe this will also fit the Longer LK2 and Alfawise U20 and U30 printers. It might also fit the Longer LK1 printer. However, I make no guarantees, and the standard "your mileage may vary" disclaimer applies. Some of the holes had to be drilled out with a 3mm or 5mm drill bit. Watch Teaching Tech's Youtube Video for more details on how to assemble everything: https://youtu.be/hs6IVfNrf5k The parts should be printed in PETG or ABS, or other high-temp material for heat resistance (I printed in PETG). Unfortunately, supports are needed for the shroud, but only for the triangular brace for the part cooling fan bracket on the side. The fan adapter allows you to use the stock 30 mm fan on the front of the shroud. I had this adapter as a separate piece rather than integrate it into the remixed part, since I'm thinking about replacing the fan with a quieter 40 mm fan. When bolting the base plate on, please be very careful not to over-tighten the bolts. It's easy to strip out the threads on the X-carriage. I ended up having to use a nut on the back of one of the bolts because the threads stripped out so badly. In most cases I chose not to use the stock bolts, and I bought some M3 pan head bolts of different sizes (M3x8, 10, 12, and 20) for most of the assembly. Bolting on the part cooling fan was tricky, and I might not have gotten the holes 100% aligned correctly on the part. You might have to drill these holes a bit wider to get the fan assembly to fit. I did not use the stock plastic spacers between the fan and grill. Otherwise, the fan nozzle would have been too close to the bed. You'll need to build and flash Marlin onto your printer. The interface is *very* different (much worse) than the stock interface. However, it works. I used platformio and Visual Studio Code to configure and build Marlin (ver 2.0.5.4). The files that I used are included. You'll need to modify the platformio.ini file to fit your particular printer. The section you may need to change is: "-DTS_V19" for the Alfawise U20 (green PCB for the screen - Version 1.1) "-DTS_V12" for the Alfawise U30 (blue PCB for the screen - Version 1.2) For these above changes, I'm going off of the Marlin notes. I have not tested this with any other printer except for my own Longer LK4. One word of warning: This is using the nozzle to home the Z-axis on the printer. At the beginning of print jobs, the nozzle *will* be hot, and it *will" melt a small hole into any build plate surfaces that aren't highly resistant to heat. This isn't too bad, as it's in one spot that's mostly out of the way.

With this file you will be able to print Longer LK4 LK2 / Alfawise U20 U30, Auto Bed Leveling - Nozzle Based with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Longer LK4 LK2 / Alfawise U20 U30, Auto Bed Leveling - Nozzle Based.