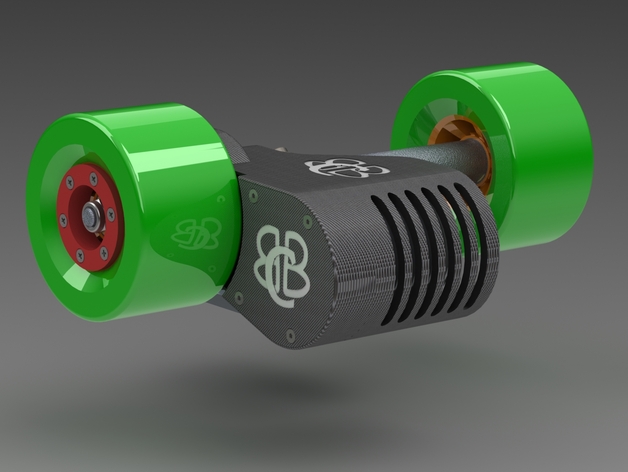

Longboard Motor Mount

thingiverse

After numerous attempts at refining my design, I've finally arrived at version 5.3, which has been put through its paces over an impressive distance of more than 500 kilometers. Throughout the various testing phases, I encountered a recurring issue - cracks would appear in different areas. This was particularly pronounced when it came to motor mounts, as they pushed FDM-printed parts to their limits. To mitigate this problem, I've introduced three essential reinforcement components. Firstly, there's the CNC-milled motor plate, crafted from 3mm aluminum. However, you can also opt for a carbon or fiberglass plate, which offers several advantages - they're easier to work with and can be handcrafted if needed. One notable drawback of using aluminum is its poor bonding properties with adhesives; I experienced delamination twice, necessitating the drilling of holes to enhance bonding. To avoid this issue, I recommend switching to CFK or glass fiber plates. The second reinforcement part is a braze component visible in the accompanying images. Its primary function is to distribute forces around the clamp screws, preventing delamination at these critical areas. When testing version 5.2, I encountered issues with carbonfill layers delaminating in mid-holes; this braze part helps mitigate that problem. You can obtain bar stock from your local hobby store (e.g., Conrad) and cut it to size using the provided template. Version 5.4 introduces an additional feature - a covered belt measuring 9mm in width. During testing, I discovered that small stones would occasionally get trapped under the belt, requiring manual removal. This new design iteration is nearing completion but is already available for those eager to test it out. Two versions are available: one for the gunmetal truck and another for the caliber truck. Thus far, only the gunmetal version has undergone extensive testing. To prepare your gun metal truck for assembly, simply file down the middle section as shown in the accompanying image - a straightforward process. I utilized an NTM Prop Drive 50-60 270 kV motor from Hobbyking, but it's no longer available. Feel free to substitute any motor with a diameter up to 50mm and a mounting hole distance of 30mm. A 9mm belt is recommended; anything wider may cause issues. I experimented with various materials, including PLA and carbonfill. To my surprise, PLA performed better than expected, especially after incorporating the reinforcement components. Carbonfill, on the other hand, boasts an attractive appearance, excellent print quality, and impressive stiffness - albeit prone to layer delamination under high forces. To address this issue, I applied a laminated carbon fiber coating to one motor mount, which not only resolved the problem but also enhanced its aesthetic appeal. My latest discovery is ApolloX from Formfutura, a material boasting exceptional temperature stability and minimal warping issues - similar to ABS but without the first-layer problems. For version 5.4, I opted for this new material and complemented it with a carbon fiber coating for added visual flair. Release History Version 0.1: Initial release Version 0.2-0.6: Iterative testing and refinement Version 0.7: Tested extensively over hundreds of kilometers Version 0.8: Released with perfect results, featuring a covered belt and compatibility with the caliber truck Stay up-to-date with my latest developments by following me on Facebook: https://www.facebook.com/berlincustomboards/

With this file you will be able to print Longboard Motor Mount with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Longboard Motor Mount.