Linear Stage Flexures

thingiverse

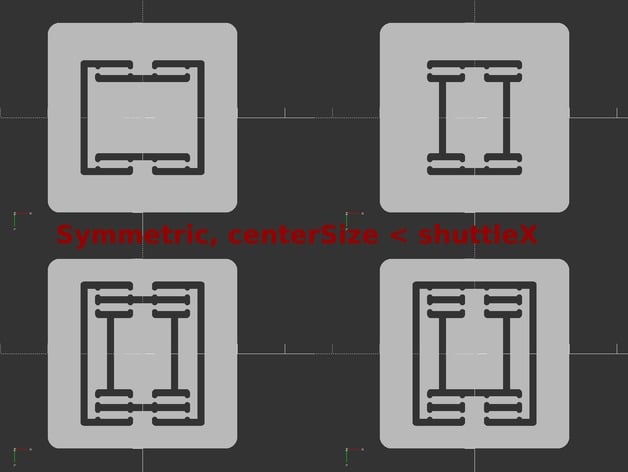

This is an OpenSCAD script delivering several modules for generating linear motion flexures(also sometimes referred to as translational compliant mechanisms).\nThese are parts designed to flex in such a way that permits motion only along one axis, while being relatively stiff to off-axis movement.\nThey are often used for applications like precise optical positioning, and when constructed of stable materials(not printed plastic) can be made to operate with nanoscale precision.\nThey can be utilized for small scale linear motion.\ Some advantages of flexures over typical slides include:\nzero backlash\nzero wear\nzero friction/stiction\ncan be easily fabricated from single block of material using subtractive mfg. (waterjet, laser cutter, cnc mill, router, EDM, etc)\nlinear motion using only 1 part\nThe patterns in this script were mainly inspired by images and videos found online showing various linear flexures, typically composed from metal or even glass.\ I tried to incorporate nearly every general pattern I found for single axis motion.\nThe flexure modules generate a 2d profile of the slots that should be cut out of your part.\nParameters used in generating the profiles are:shuttleSize: [x,y] dimensions of the inner piece which moves\nslotWidth: Width of slots which are cut from the part, determines max travelbeamLength: The beams are the parts which are designed to flex. Longer beams may be necessary for stiffer materials.\nminWidth: The beams can be notched down to provide more flexible pivot points on the ends, this is the minimum they will be notched down to.maxWidth: This is the width of the beams in all places where not notched. If minWidth equals maxWidth, there will be no notches. Both minWidth and maxWidth should probably be a multiple of your nozzle diameter.\nnotchScale When maxWidth is only slightly larger than minWidth, the notch will be a very tiny semicircle. Notch scale stretches this circle wider to a more reasonable feature size, without affecting the minWidth of the beamcenterSize: This is the distance between the left and right beams Only used with symmetric designs. It should be greater than or equal to maxWidth for strength. Also less than or equal to shuttleSize X dimension. If set equal to shuttleX, the beams will be placed on the side of the shuttle and the overall pattern is vertically shorter.\nThe provided STLs and Customizer are available as examples of the various configurations possible using this script, but for real applications you will likely want to specify your own bolt holes for anchoring the part, and means of adjusting the position.\nFor an example application see my Z-Probe Mount here: http://www.thingiverse.com/thing:1119715\nAnother idea is to use a printed flexure as a spring for a vehicle suspension, or maybe vibration isolation feet for a printer.\nSome flexures in the wild are multistage, providing x and y motion for example. I have not experimented with this, but it should be possible to nest a single axis flexure inside another(rotated 90degrees) to provide 2 axis motion.

With this file you will be able to print Linear Stage Flexures with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Linear Stage Flexures.