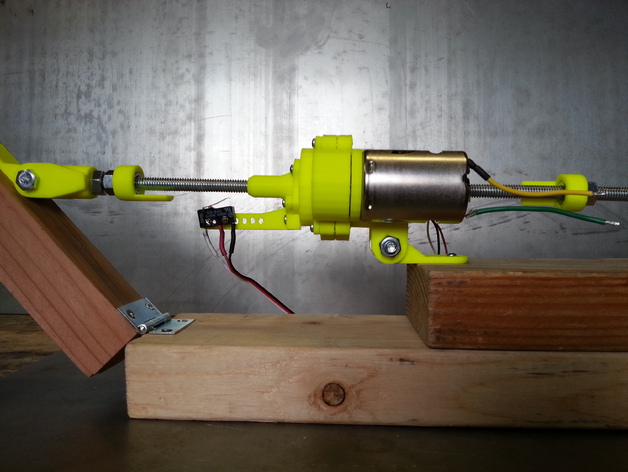

Linear 31, 5/16-18 Thread

thingiverse

Another High-Performance Linear System that Gets the Job Done! This Ultra Versatile Linear can be used with several sizes of motors from 270, 360, 370, 380 up to the powerful 540. Utilizes 5/16-18 all thread rod and precision spinning hex nuts for motion control. The only limit is linear travel based on how long of threaded rod you have. Offers a range of gear ratios that can be used to achieve the perfect speed and power. Can mount up in multiple ways, with mounts for miniature micro switches included. Can push or pull through a bulkhead with ease. The Linear system is compact enough to fit beside a 2 by 4 with motor laid on its side. With the addition of a motor speed controller, this Linear can be used to move any object remotely. The linear comes in two different A-case configurations depending on the desired motor size. The larger 540 case can accommodate motors with 25mm mounting holes and a 1.409" diameter. This setup will also fit with larger pinion gears but requires additional support to prevent damage. The smaller 380A case, on the other hand, is designed for motors with 16 and 17mm bolt centers, with a maximum motor OD of 1.092". Gear ratios for each case range from 93-14 for the 540 case and 93-10 for the 380 case. The spool assembly features two sealed RC truck bearings (18x12x4mm) to ensure smooth operation. The gear ratio can be easily calculated using the provided .PDF chart, showing available combinations and ratios. When it comes to determining speed, the user must first calculate the multiplier by dividing pinion teeth by spur teeth (93 for example divided by 14 is approximately 6.643). Multiply this number by motor RPM, then divide that result by thread pitch of all threaded rod (which is .05556) to find the distance traveled per second. A 540 motor with a gear ratio of 93-14 can handle heavy loads, such as deadlifting a 5lb hammer, while using the linear system's built-in vise for added stability. Smaller motors and lower RPM setups will slow down but are recommended for more precise control. Users should note that smaller gears provide higher speeds but lower torque. In terms of electronics, wiring the motor up safely requires attention to amperage ratings, as micro switches must be rated for 12A at DC volts not VAC (Volts Alternating Current). When connecting Arduino boards and relays for control, use care with DC amps versus AC Amps ratings. Switch holders offer flexible installation options, allowing placement on various angles. With a few sheet metal screws (#4x3/8, #4x1/2), mounting to the case can be achieved. Tapping threads in mounting brackets and the yoke using a 'F' bit may be necessary for optimal fitment. As this system is still under development, stay tuned for updates on how it handles real-world usage, wiring solutions for various configurations (including automotive relays and toggle switches), and possibly improved or replacement gear components suitable for the higher power of 19,000 RPM motors. A useful addition was recently incorporated: access to pre-made Team Associated Spur Gears available for download. Using manufactured 48P pinion gears (be they metal or plastic) will yield better results with the system, particularly with lower-torque applications where smaller motors may be beneficial. Since last update (June 2015), an exciting alternative motor option has been identified - the Jameco Mabuchi RS555PH-2330 (#2144673). This high torque (380g-cm) and slower RPM motor is much easier to manage at only 4A, suitable for a wide voltage range. Users can expect to spend $3.95 each on these more affordable motors, opening up new possibilities in high-power projects like lifting heavy objects or parts.

With this file you will be able to print Linear 31, 5/16-18 Thread with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Linear 31, 5/16-18 Thread.