Lee Reloading press Case Retention Flap

thingiverse

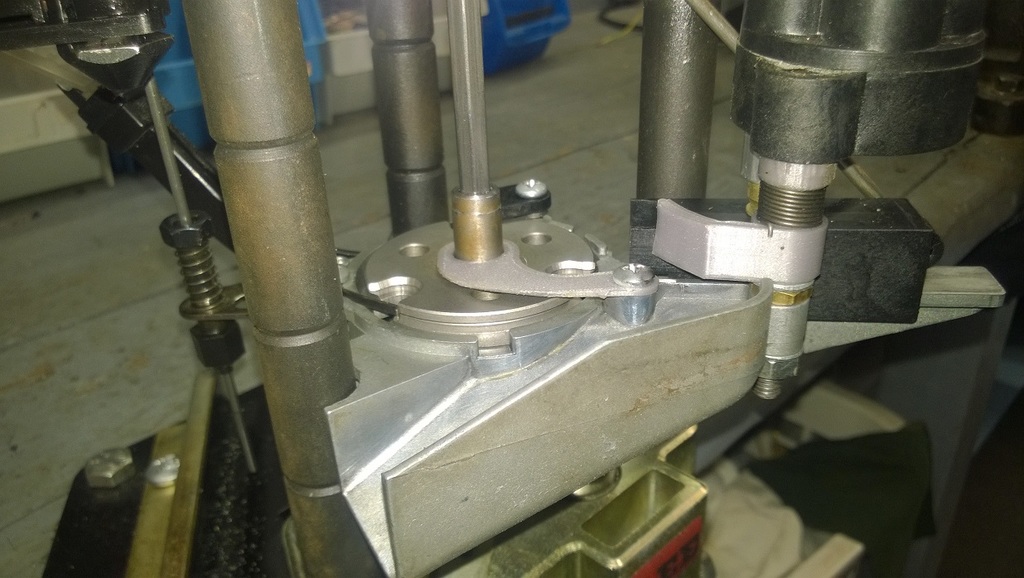

Improvement for Lee progressive reloading presses in form of case retention components that are to be added to stock press of following type: Lee PRO 1000 , Lee LOADMASTER, Lee AUTO BREECH LOCK PRO These components are designed to fit for stock press with one exception - the original (imperial) screw which is used to hold the case feeder assy is to be replaced by M6x70 (or longer) metric fully threaded screw with hexagonal head. Apart from the metric screw you need also some washers, one standard M6 nut and one low profile M6 nut (brass color on picture). You need also to get a torsion spring that will actuate the flap. I've wound mine on lathe from 0.8mm spring wire, OD 12mm, L 10mm. You can for sure find a suitable variant among common torsion spring sets sold on eBay. Optionally you can use washers to set the right height of the flap for case you reload. Components "zachyt pruziny..." will accept M6 nut and contains 4 small holes on bottom part that you can use as spring catch. You can optionally select option with or without spring support/retainer, depending on your spring design. Component "packa..." may need slight adjustement of the flap angle in order to accurately fit given press (there are slight part2part differences among the press assemblies). Shaping after heating part by hot air works fine. Function shown on shared videos.

With this file you will be able to print Lee Reloading press Case Retention Flap with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Lee Reloading press Case Retention Flap.