Lead_Screw_Bracket (Self-Adjusting)

thingiverse

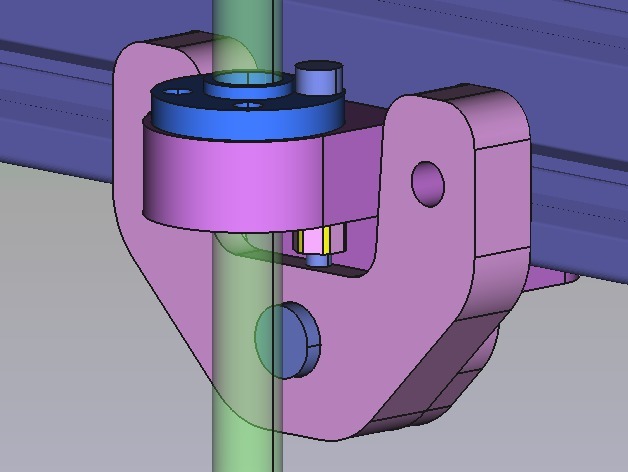

I strongly believe that a fixed Lead Screw Bracket, similar to the D-Box, is asking for trouble. It assumes that the bed supports will be perfectly horizontal, which they never are. Close, but not quite. The lead screw nuts can tolerate a bit of an angle against the lead screws, but not much, and it's not meant to be that way. Before you know it, the torque results in more friction than the stepper motor wants to handle. These self-adjusting Lead Screw Brackets can handle that angle without bothering the lead screw nuts with it. There are two versions: one full plastic, called simple, and another with ball bearings. After making the full plastic version, I started wondering what would happen if the pressure between the two parts affected the friction over time, as plastics tend to do. It worked exactly as planned, and I believe that after mounting, very little, if any, adjustment is needed until something changes that affects the bed supports' position. I'm not sure whether at that point the parts would have become more fixed on each other, preventing self-adjustment, or not. Honestly, I don't know enough about plastics to be certain one way or the other. So, I made a version where the pressure is left to a ball bearing. It's a bit more complicated than the straightforward all-plastic version, so I thought it would be best to offer both versions and let you decide which one to use. I printed everything without support, and TLC remains necessary with or without support. For the first version, I used 4 M5x16 bolts + washers + hammer heads and 4 M3x18-20 bolts + washers + lock nuts. Not more than 20mm due to the room needed for rotation. The distance between the bed support and lead screw remains the same as before, so you can swap out parts without moving the stepper motor mounts. For the version with a ball bearing, I used: * 1 Ball Bearing MR105ZZ (ø5xø10x4) (the same one used for wheels) * 2 brass shims ø8xø5x1 * 1 M5x16 bolt + washer + lock nut Check the images: the shims are not symmetrical with respect to part 1, making it easier to print. And again, 4 M3x18-20 bolts + washers + lock nuts for the lead screw nut. As you can see, there's just room for longer bolts. I'm sure you'll need some TLC to fit the ball bearing into part 1 because I made the hole ø10mm, same as the ball bearing, although I believe that there's always pressure downward and extra room would be taken care of without causing problems. But perhaps I'm wrong, so now you can make it fit nicely. For part 2, I used 2 M5x16 bolts + washers + hammer heads. Check that the bolt-head from the ball bearing assembly goes easily into the lower hole of part 2. For part 3, I used, apart from the ball bearing stuff, 2 M5x10 bolts + washers + hammer heads. In this version, there's 1mm more distance from the bed support to the lead screw compared to the original, so you want to check the stepper motor mount places. It was necessary to have some room for the ball bearing bolt and I wanted to use the usual variety of bolts, not the ones with flat heads. In both versions, you need to check after mounting whether there's enough play for part 1 to move freely without binding. I edited this post on 10/01/18: Things looked so bad for a moment that I thought this thing was seriously flawed because all of a sudden the lead screw went very much askew when I lowered the bed completely, but now I had time to look at it again, I think that shit happened because I let this thing crash into the flexible motor coupling. I don't think it's a good idea to make the thing thinner to make room for the coupling, so I leave it as it is with the warning that you should check your lower z-endstop to prevent it from happening to you. Looking at the thing more closely, I saw that it just worked better than I thought in the sense that you could see the angle change just a little bit when the bed travels from high up to completely down, as it should, of course, because the angle between the bed supports and the lead screw changes a bit when moving up and down. The more reason to feel that this thing is necessary. And again, this movement diminishes the chance that the complete plastic thing gets fixated, when one uses that. At the same time, I think that I prefer the ball bearings even more because I feel that those can follow these small changes easier.

With this file you will be able to print Lead_Screw_Bracket (Self-Adjusting) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Lead_Screw_Bracket (Self-Adjusting).