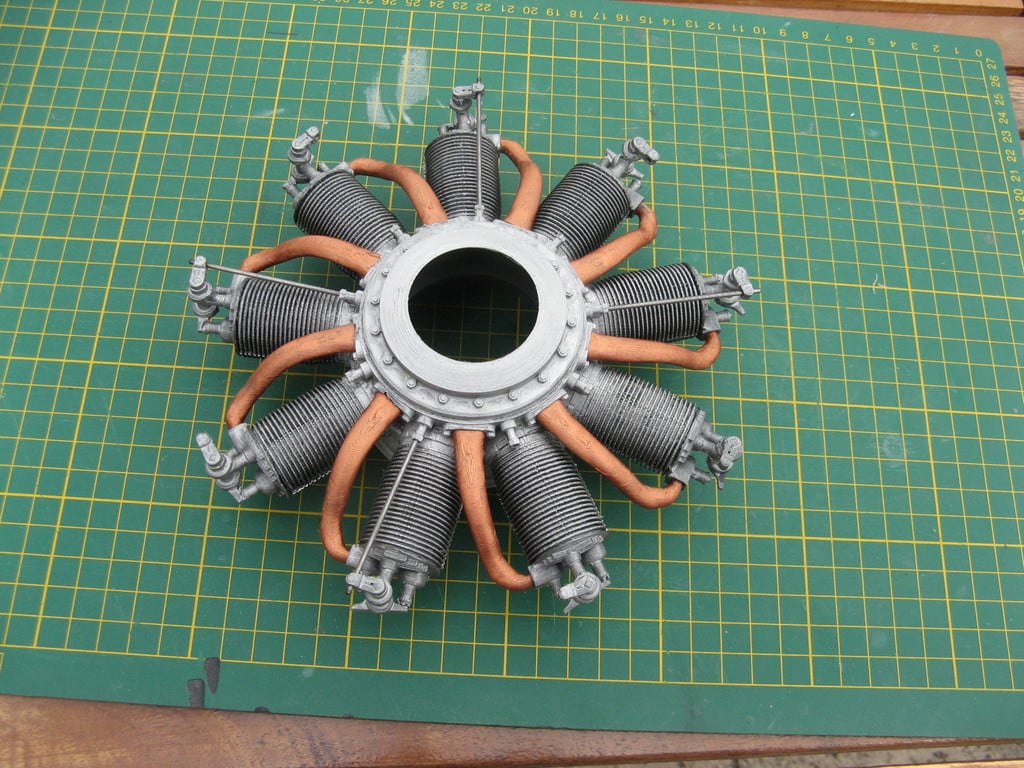

Le Rhone Rotary Engine

thingiverse

I designed this engine to fit snugly within a 1:5 scale Sopwith Pup I'm currently designing, taking into account its unique specifications. The design deviates from my previous work in that the cylinder heads require separate printing due to the complex valve gear. Printing a simple, vertically split engine would be impractical. The crankcase and cylinder halves were successfully printed on a Creality Ender 3 without supports or brims. I opted for only a skirt to ensure smooth print flow. The inlet tubes, however, required additional support, with their fronts facing upwards and the support overhang angle set at 80 degrees to minimize excess material. Cylinder heads were also printed with "supports everywhere" enabled, along with a reduced support overhead angle of 70 degrees. Pushrod rockers feature holes designed for easy insertion of 16swg piano wire or 1.5mm carbon fibre pushrods. To facilitate smooth rotation, the engine is equipped with ball bearings that allow it to rotate freely. As printed, it's intended to run on four small bearings fitted into a track located at the rear of the engine, as visualized in the CAD sketch. The joining ring is carefully glued into the front half of the engine before assembly, ensuring proper alignment between the two halves. This motor also boasts an impressive weight, with all-up weight featuring piano wire pushrods reaching approximately 140 grams (5 ounces). While it may seem a bit heavy, most WW1 models tend to be tail-heavy, making extra weight up front a desirable trait. Scale detail always takes precedence over lead weights in my designs.

With this file you will be able to print Le Rhone Rotary Engine with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Le Rhone Rotary Engine.