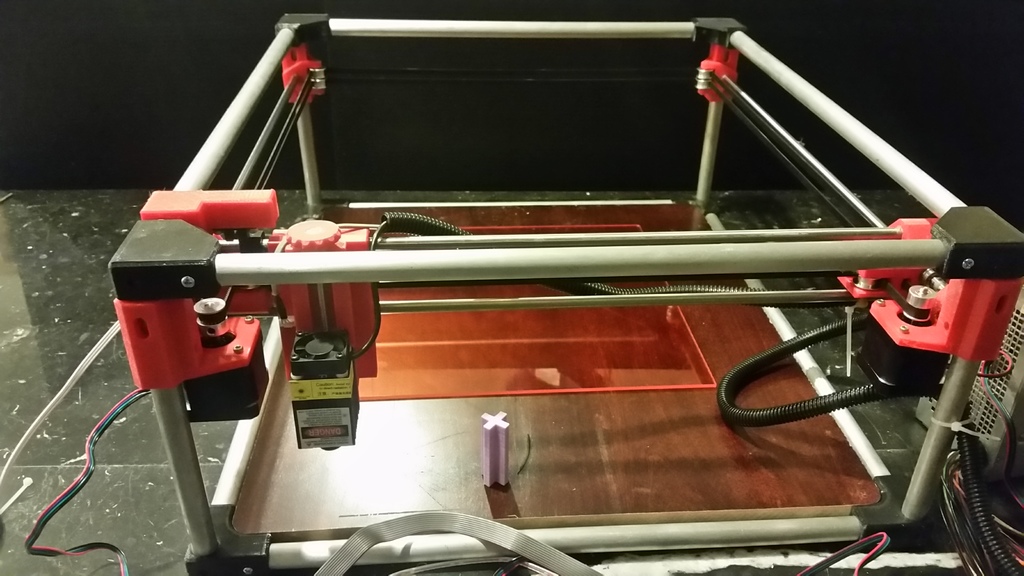

Laser Tube Cube (based on Hypercube Evolution)

thingiverse

<h3><font color="red">WARNING: These lasers are not toys and they can cause serious harm! Make sure you wear protective eyewear when operating them!</font></h3> Update 3/15/2018 It's time to wrap up this project. Spring is here, and I'm eager to get back to my other passion, USPSA/IPSC. I've posted some final pictures, but unfortunately, I didn't have a chance to build a mount for the RAMPS/LCD. However, I did purchase a GRBL CNC shield, which I might use in the future. If you buy the v4 version, be aware that you'll need to side-load the UNO bootloader onto your NANO, or it won't work with the CoreXY setup due to space constraints. Here's a <a href="https://youtu.be/DkQT_V0U6Ys">video</a> of a sample cut on cardboard. Enjoy! Sincerely, Triggermeister P.S. I think it would be exciting to convert a CTC i3 or ANET A8 into a Tube Cube 3D printer by using as many parts as possible and buying only the necessary materials. This could be a game-changer... Update 2/28/2018 I've implemented a decent cable management system, thanks to https://www.thingiverse.com/thing:11978 for a cable chain on the Y-axis and a standard cable loom. I uploaded a new Y endcap and two loops for the cable loom, which requires three brass inserts. Pictures will be added later today. Update 2/25/2018 I've installed an enclosure, but I'm still working on cutting the press board for the "laser-proof window" with an OD of 3. I created four L/U channels that were solvent-welded to the corner pieces, allowing me to easily slide in the sides and remove them when needed. The top will sit on top of the corner pieces and be held in place by the longer sides. I also need to focus on cable management, as the cable loom was dragging and getting cut by the laser. I caught it just in time before the cables were damaged. In the printer configuration, I generally have enough "wasted space" at the back for the drag chain to bend, but without a Z-axis, you can use the entire Y travel, so I need to come up with an alternative solution. Without a case, the choice would be easy, but my current idea is to use a cable chain for Y and a spiral wrap for X with a loop/holder on the X-carriage and left Y-carriage. If you have any ideas, please share them in the comments! <hr> This project started with an impulse purchase of a 2.5W laser, followed by rummaging through my leftover bin to find key components to build the 3D printer/engraver. I printed the parts and then decided to stick with the Core-XY concept. Using 5/8" aluminum tubes instead of expensive extrusions seemed like a great idea. So here's my rendition of the Tube Cube HEVO Engraver. Wait, isn't this actually a 3D printer? You could easily make it into one by adding a Z-axis... BOM: * 5/8" or 16mm tubing aluminum (steel could also work) Y-axis 500 mm = 400mm print area X-axis 440 mm = 300mm print area Z-axis 220 mm * 4 x 8mm linear rails Y-axis 500 mm X-axis 460 mm * 8 x 8mm linear bearings * 1 x RAMPS 1.4 * 1 x Arduino Mega * 2 x Stepper drivers * 2 x Stepper motors * 1 x Power supply * 100 x brass 3mm inserts * Bunch of screws (some sheet metal, nuts and bolts, etc.) * Number 10 x 3" screw with 4 nuts for the Z adjustment * 6 x tooth pulleys T20 * 2 x smooth pulleys T20 * Some PLA BONUS: * Added my other corner piece that allows you to pass vertical tubes through it. This will come in handy if you want to build a dual Z-axis Tube Cube. It wasn't necessary for the engraver version, but it might be useful in the future. (Lightweight_midpiece)

With this file you will be able to print Laser Tube Cube (based on Hypercube Evolution) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Laser Tube Cube (based on Hypercube Evolution).