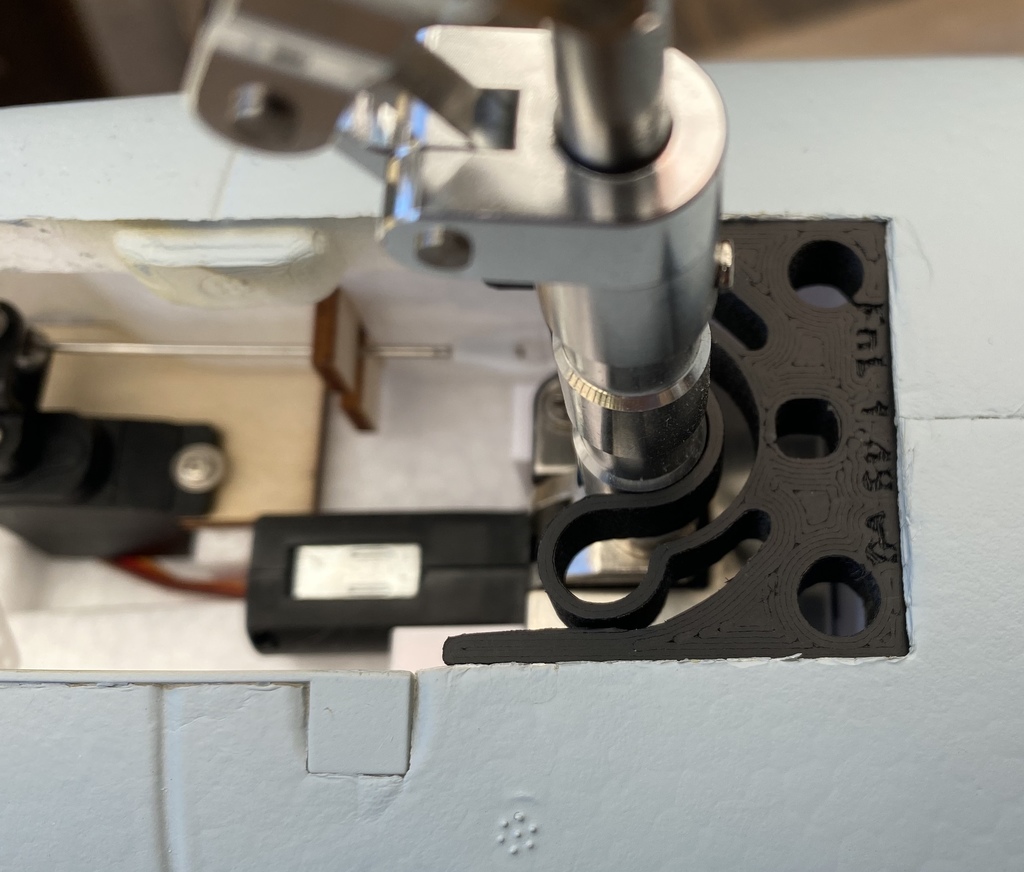

L-39 Flex Brace for Nose Gear on Freewing Albatros

thingiverse

CAUTION: This design has been bench tested ONLY! If you install and fly it you may be the 1st to do so... This Flex Brace is an alternative to the typical rigid nose gear supports. It makes use of the elastometric properties of polymers and the shape forming capability of 3D printing. The web thickness of the Brace 'spring' and type of filament will both affect the stiffness/reaction force. Based on my observations, the spring seems to have a non-linear force response which increases with deflection. Design intent is to better distribute the aft and lateral forces on the nose gear between the 1) gear primary structural support , 2) fuselage foam on the perimeter of the brace Potential benefits include 1) Improved nose gear & attachment durability 2) Reduced damage to fuselage foam on the perimeter of the brace compared to typical rigid supports 3) A two stage lateral spring stiffness to reduce the likelihood of retract force overload due to minor misalignment CAUTION: Consider operating temperature range when selecting filament. Some polymers become brittle at low temperatures and could fail with 'normal' deflections. Some soften with increased temperature which could affect performance. The design is intended to be adhered to the fuselage on the entirety of the Brace perimeter. Select an adhesive which is appropriate for the foam and filament. My preference is FoamTac if the filament is compatible. White Gorilla Glue is my 1st alternate.

With this file you will be able to print L-39 Flex Brace for Nose Gear on Freewing Albatros with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on L-39 Flex Brace for Nose Gear on Freewing Albatros.