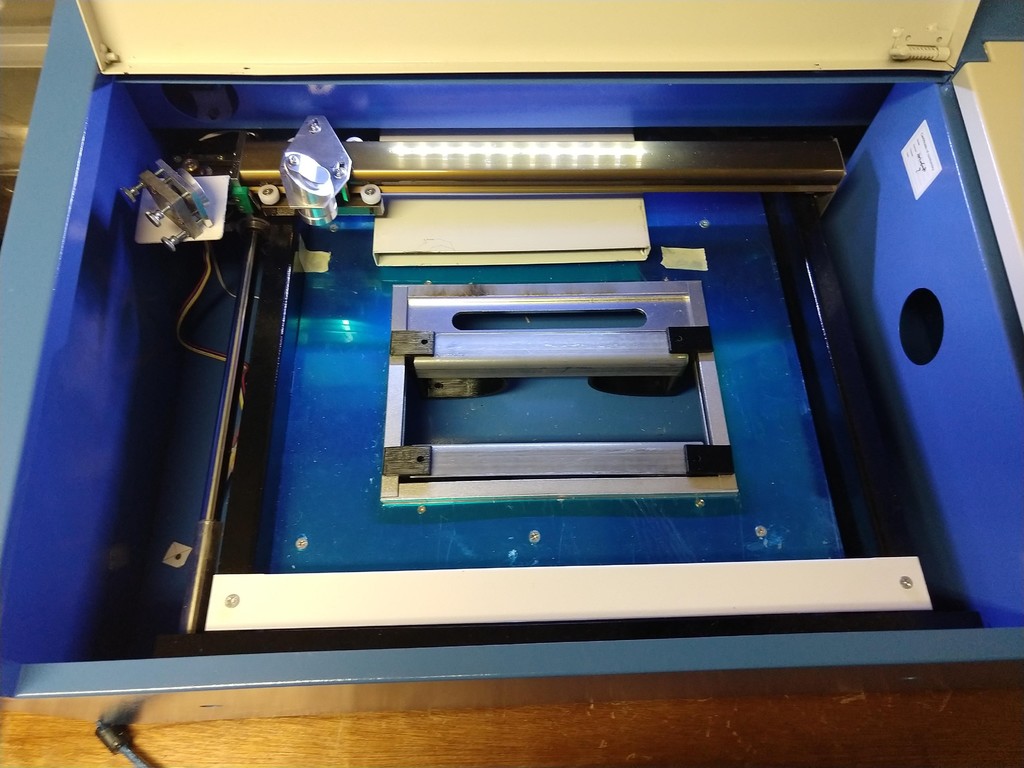

K40 laser work area side brackets with spring

thingiverse

I previously submitted a design for "K40 Laser work area brackets - without spring" which included a detailed explanation of this type of material support system. This revised submission adds an extension that functions as a spring, eliminating the need to purchase additional hardware to make it operational. However, you will not have the option to upgrade it with precision adjustments like those achievable using machine screws. I recommend utilizing metal bars for supporting materials to prevent laser cutting into plastic and causing damage. Wood or acrylic scraps can also be used as alternatives. A grid design printed on cardstock is included in this submission, positioned at the lower left corner against the brackets as shown. This grid was lasered onto the cardstock, and its position was recorded at the laser's center point. This information will serve as a reference for positioning designs within the work area. In my laser machine, the focus is situated approximately 8mm above the frame. As a result, the glass bead is positioned correctly without requiring spacers to press against the bracket springs. The grid design was printed using a Davinci 1.0 Pro with PETG material and default settings, except for increased infill density for added strength. The printing time for this item was approximately 2.5 hours. To ensure proper orientation, rotate the design so that the angle support part is facing downwards against the bed.

With this file you will be able to print K40 laser work area side brackets with spring with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on K40 laser work area side brackets with spring.