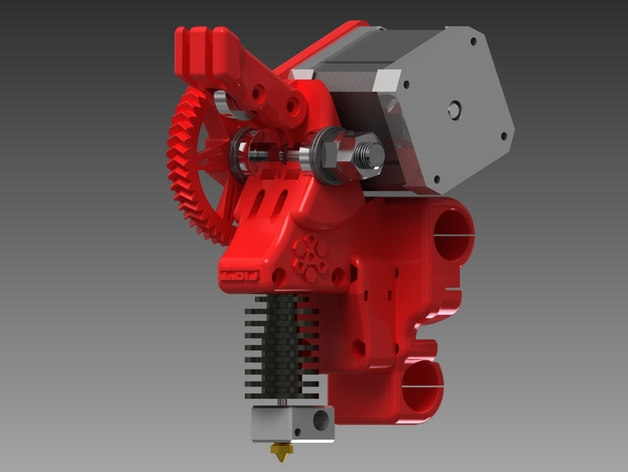

Infill 3D 75 Geared Extruder

thingiverse

As I mentioned earlier in my post about Infill 3D's Bowden geared extruder, I strongly prefer direct drives for their sleek appearance, reduced part count, and less complex design at a price that comes with trade-offs. Aesthetically speaking, I firmly believe direct drives are the way to go - they offer a clean and minimalist look without compromising too much on reliability. Once again, I aimed to create a compact extruder boasting the reliability of Wade's design, which has always been the gold standard for this purpose. That is why I've developed the following product. I created this new extruder with direct drives in mind and compatible with the SunBurn hotend from Infill 3D as well as their i3R kit; it should also work seamlessly with any other 16mm groove mount hotends that you might prefer. This device has been designed to provide maximum space savings by maintaining a total distance of 10 mm +/- from the X-carriage to the tip of the SunBurn hotend, which could have easily been optimized but I preferred playing it safe for practical use. Moreover, the extruder employs exactly the same miniature 2/3 herringbone gears that I've successfully used in my previous designs, hence offering an equally compact profile as evidenced by the included pictures; check out one of them, if you will, to appreciate just how small this gadget really is - a quarter dollar coin has been strategically placed on the photograph for comparison. So far, after putting it through extensive testing over several months now, my creation continues to deliver consistent and excellent performance results every single time. The updated design including the X-carriage is conveniently available online at http://infill3d.com/20-downloads along with various other supporting parts which you may find beneficial for use with Prusa i3 models. Please don't hesitate to share any suggestions or point out potential errors - all of your feedback would be gratefully received. Instructions As it so happens, I have several pre-made X-carriages at my disposal that were designed specifically for this direct drive extruder setup; you will notice they have been integrated with a clever notch design to accommodate conventional-sized gear-based extruders in the event that you prefer to upgrade to something else check the downloads area on my site. Given some components do come out pretty small I highly recommend that all relevant parts should be printed simultaneously in one session rather than leaving it open and facing the associated heat issues. Now here are a few of things that you might need... 9 x 688ZZ Bearings (3 for Extruder and Idler) 30 x M3 Nuts (For idler clamp carrier Extruder extrusion motor mount bracket etc.) 4 x M3 Washers (To hold down springs, for springs only to make easier when needed) 8x M3X18 Socket screw (For Idler extruder etc.), (Motor to Mount 3 screws of these will need adjusting as different sizes exist and might require a washer too or depending upon where you choose) (exactly the right lengths) 12 x M3X45 Socket screw 10x 4M8 Washers 7 X Nuts M8

With this file you will be able to print Infill 3D 75 Geared Extruder with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Infill 3D 75 Geared Extruder.