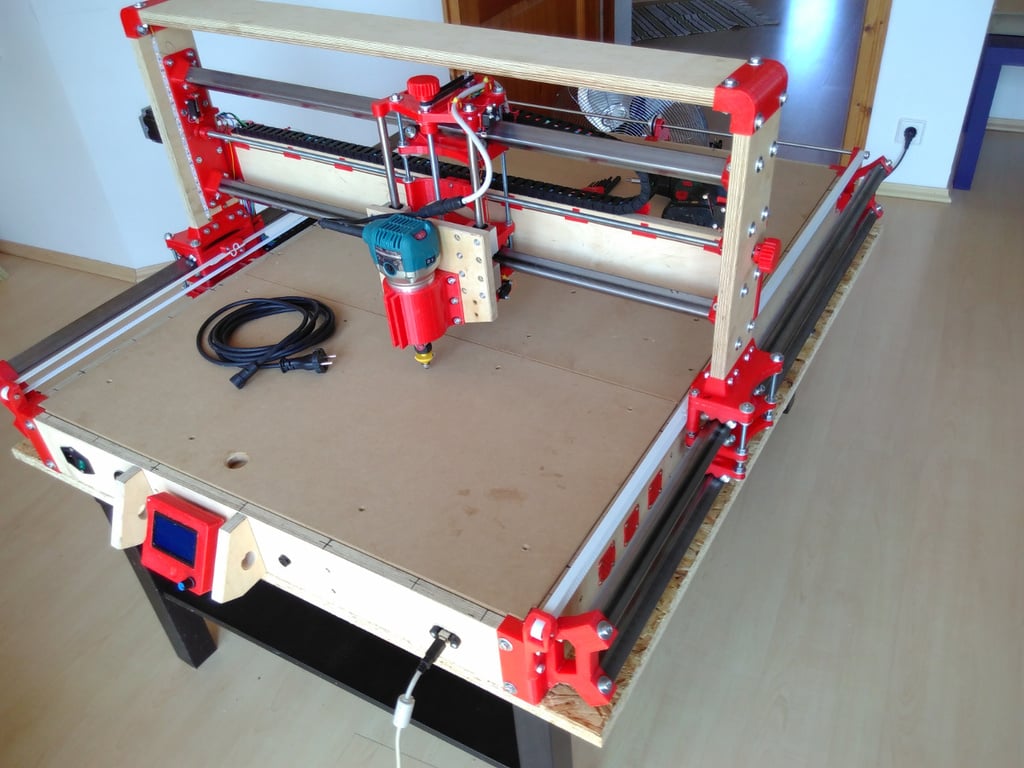

Increased milling space for R-CNC, the printable milling machine

thingiverse

I am currently modifying a customized version of [R-CNC, the printable milling machine](https://www.thingiverse.com/thing:2159840). Since the original design is too small for my woodworking needs, I plan to enlarge it significantly: Increasing the width is straightforward: add 200mm to all the original measurements. Adding more depth is a bit trickier as sturdiness deteriorates exponentially when only increasing the length of the side tubes. In a first step, I will use the original 25mm tubes but extend them to 1200mm and test bending. Simply adding 450mm to all the original measurements should suffice. If bending proves too challenging, I will either swap the corner pieces with holders for 40mm tubes or add a second 25mm tube below - which is more complicated and less likely to happen. This alternative solution is already included in this upload. Another simple approach might be to insert a matching flat bar vertically into the tube and glue it along the full length of the corners. Maybe just filling the corners with epoxy resin would work. Adding more clearance below the router requires stretching the x-fixations and shifting them upwards. All the original measurements are increased by 50mm, except for the two side pieces which will likely need an additional 80mm. Since the resulting X-fixation was too large for common 3D printers like mine, I cut it in half and added small hooks. You may need to file the hooks a bit once printed. There is also an updated drilling template available for paper prints. To use it correctly: print it, calculate the required scaling factor by dividing real measurement on paper by the printed value. Then print again. Afterwards, fold it at the designated line and place the fold at the front sides to mark the locations. Be sure to shift equally on both sides. Please note that this is a work-in-progress design and some details may change for better performance. ***Update 2017-07-23:*** I am almost done with the project ;-) Contrary to initial assumptions, a 40mm tube is too large; it covers part of the space for the belt. So I added a second tube with 25mm below the original one. Additionally, there are screws in the bottom board to support the second tube. This project now contains all my files. Each STL file is accompanied by a JPG of the same name so you have an idea about the intended purpose and location. I omitted the Sketchup files; if you need them, please let me know. I modified the Marlin files slightly to make the endstops work and display the current state on the otherwise empty space on the LCD. I also added support for a Z probe which acts as a second ZMIN for homing. Now I can wire up the router bit and place a thin piece of wired metal on top of my stock, and it will home correctly. ***Update 2018-03-04:*** The sources with my modifications are all available on [Github](https://github.com/ewanold/marlin-cnc) Since Marlin was not designed as software for a CNC, it does not understand every such gcode file. My current workflow includes FreeCAD and the LinuxCNC or GRBL preprocessor. Just make sure that the output is not shortened; each line must contain X, Y, and Z-code like the following: `G0 X109.8144 Y548.0000 Z13.0000`

With this file you will be able to print Increased milling space for R-CNC, the printable milling machine with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Increased milling space for R-CNC, the printable milling machine.