Improved Extruder, Hotend and Fan Mount for rp3d Pangu Wooden i3

thingiverse

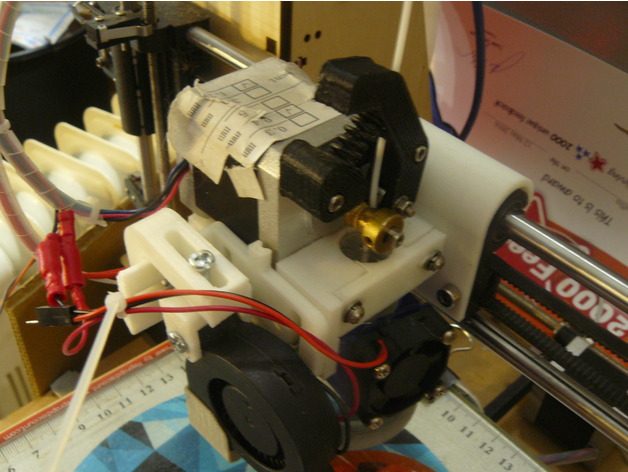

This mount is designed specifically for the rp3d Pangu Wooden i3, which features an X carriage with 2.5 inch (63.5mm) mounting hole spacing and a radiused top and bottom. Let's get straight to the point - the original mount provided by the manufacturer is flimsy, unstable, and lacks adequate space for attaching support fans or other components. Furthermore, it cannot accommodate cheap all-metal hotends from China. This new design addresses these issues, offering multiple attachment points for future modifications, compatibility with metal hotends, and a fan mounting system that simplifies alignment of the eesteven's no-notch fan with a blower. It is essential to note that you must use both a hot-end cooling fan (attached to the hotend heatsink) and a layer cooling (blower) fan. If you use the hot-end cooling fan, you can print the mount in PLA without any issues; however, ABS or high-temperature printing may require additional precautions. To source a suitable hotend with fan, search for "Short Distance" or "Direct" head on Aliexpress, as these are more compatible than "Long Distance" or "Bowden" models. Some recommended sellers include Hotend With Fan, MT Technology Co., Ltd., Hotends Only, 3C Mall Center, and Hotends Only, ANYCUBIC 3D-Printer Store. For fans only, search for "reprap injection fan" on Aliexpress to find affordable options under $2 USD. Make sure to have a cooling fan, as it is crucial for the mount's functionality. Print Settings: * Printer: rp3d Pangu Wooden i3 * Rafts: No * Supports: Yes * Resolution: 0.35 * Infill: 20% * Notes: + Print the main mount end-on. + Print the clamp flat side down. + Print Fan Bracket Part A on its edge, oriented as it will be used to ensure a strong right angle and not a weak spot from layer adhesion. + Print Fan Bracket Part B flat for the same reason. + Print Fan Bracket Part C (U bracket) upside down, with the U facing up. Post-Printing: * You will need M3 screws, washers, and nuts, as well as M4 screws and nuts. At least two M3 screws should be at least 30mm long for the clamp and motor mount. * Insert two M3 nuts into the back side of the front face of the main mount, securing them with superglue or a similar adhesive. * Assemble the main mount on the existing X carriage by aligning it with the valley (inverse ridge) in the back. This allows for "elephant foot" compensation and ensures proper alignment. * Snap in your metal hotend and attach the extruder motor to the platform. Thread filament through to achieve a reasonable feed path, then secure everything with screws. * Insert two M4 nuts into Fan Bracket Part C and glue them in place. * Attach Fan Bracket Part B onto Part A, followed by attaching Part C onto Part B to create the U-shaped structure. * Screw Fan Bracket Part A onto the mount but leave some room for adjustment. * Lower the Z axis and set the Z limit switch so the nozzle is in the correct position. Raise the Z axis slightly and insert your blower fan with its fan-duct attached into the downward-facing Part C, securing it with an M4 screw. * Adjust the fan's position and height off the bed by moving Part A up and down, part B in and out, and rotationally in the Y axis. You can also adjust Part C left and right and rotationally in the Z axis, as well as the fan itself rotationally in the X axis. With some minor adjustments, you should be able to achieve a flat, centered, and raised fan duct. Design Details: This design was created using OnShape, and you can copy and edit it here if desired.

With this file you will be able to print Improved Extruder, Hotend and Fan Mount for rp3d Pangu Wooden i3 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Improved Extruder, Hotend and Fan Mount for rp3d Pangu Wooden i3.