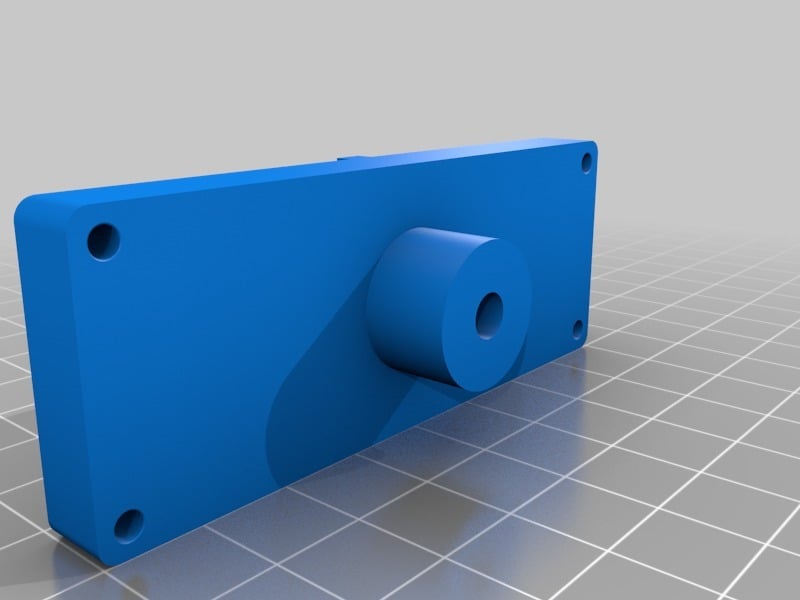

ICOM ID-4100 head mount

thingiverse

ICOM ID-4100 Head Bracket V1 ============================ After the original bracket broke, I decided to create something better. ICOM is great, but their proprietary mounting system leaves much to be desired. As such, here's a new bracket that will accommodate your unique ideas and designs or complement/replace the original. If used in a vehicle, use PETG/ABS or another temperature-resistant material. ============ **There are two design options: one piece and two piece. If you only want the front section that fits on the radio, print the "Head_Unit_Mounting_Front" file** What's needed: ----------------------------- - **Mount with a 1/4-20 UNC Thread** (like camera tripod mounts work well if you want to suction mount it). - **Epoxy**: good epoxy to mount the washers in place (you can bolt them in so long as the washers are countersunk, but I use epoxy to keep things flush). - **Star washer** for the 1/2 inch to hold it to the plastic shank firmly. - **Two steel or iron washers**: if using magnets on the radio head, they need to work. If you're simply drilling it out and using screws to hold the head, don't worry about them. - You can tap the 1/4 into the plastic or use a brass insert. I personally have tapped the plastic and it seems to work just fine. Method (considering you used the one-piece document) ----------- **1.** Test fit the radio head before moving on. Ensure the head fits within the extrusion and the tabs are aligned. **2.** Either use a tap or a warm screw to tap the rear shank, The hole is designed to accommodate a 1/4-20 and is already threaded by design. However, most printers are not able to print them properly. If yours does, you can skip this step. **3.** Test fit your tripod or mount. I personally use a flat mount with a standard hex-cap bolt from the hardware store, but tripods work very well. The shank is designed very deep to allow threading the bolt quite far for better stability. **4.** Place washers in the indents. Due to the millions of washer styles available, it's hard to recommend which ones to get. They need to sit flush with the magnets on the radio and with the bottom of the mount. Determine how many you will need. I had very thick washers requiring only two on either side (four total). **5.** Epoxy time! Mix your epoxy and apply between layers of the washers to final height. I use 5-minute epoxy and hold the parts with clothespins. Once those are cured, apply epoxy to circular indents and place the washers into the center of the indents. **6.** Once the epoxy has cured, ensure the fit is good. Place the star washer between your mount and the radio, tighten as far as possible while maintaining the desired orientation. Your mount should include another nut or sleeve to tighten the remaining threads. TWO PIECE ======== The two-piece mount is provided as a better method without using supports. Also, you can simply print only one half to use as a mount for anything you want. They can be held together by your choice of hardware. I personally tapped both sections and used a black hex-head screw with no washer.

With this file you will be able to print ICOM ID-4100 head mount with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on ICOM ID-4100 head mount.