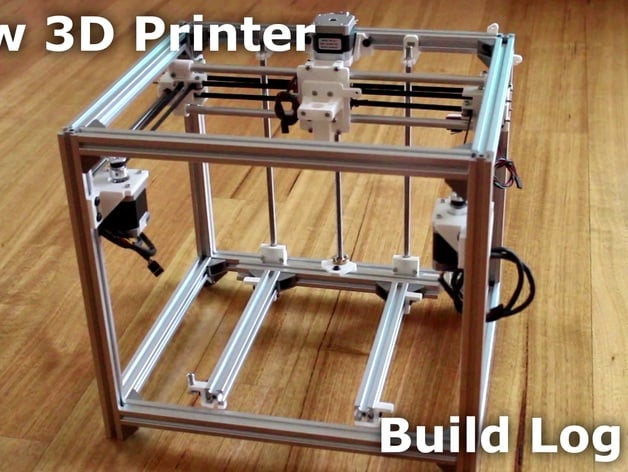

HyperCube 3D Printer/CNC

thingiverse

This is a versatile CoreXY 3D Printer and CNC machine frame. Upgrade your existing printer with this robust build! Reuse your motors, electronics, hotend, heatbed, and other components to save time and resources. Watch the development of the HyperCube in action: https://www.youtube.com/watch?v=n2jM6v3E7sU&list=PLIaArjwViQRVAERWRrYfe9rtiwvvRGCzw To minimize weight, I chose to use 10mm anodized aluminum tubing for the X-gantry rails. This reduces the moving mass significantly, as the entire X-gantry moves in the Y direction. The use of 8mm steel rods would be twice as heavy. Since then, I've upgraded to Carbon Fiber tubes, which is one-eighth the weight of 8mm steel rods. Marlin 2.0.1 Configuration.h and my custom firmware.bin files are attached for your reference. Bill of Materials (BOM): Frame: T-Slot 2020 (Slot/Type 6) Aluminum Extrusion Profiles for a print bed area of X200 x Y200 x Z155: * Buy from Banggood - Silver, Black * Buy from Amazon Required Components: * 4 x 340mm (X) * 4 x 303mm (Y) * 4 x 350mm (Z) * 2 x 285mm (Bed) * 1 x 135mm (Bed) Fixings: * 60 x M5 x 8mm button head screws * 60 x M5 x 10mm button head screws * 2 x 100pcs T-Slot M5 hammer nuts * 3 x 10pcs Aluminum Corner Brackets CoreXY + Z + Bowden Components: * 2 x 8mmx300mm Hardened Steel smooth rod (choose 300mm length) for Y axis * 2 x 12mmx400mm Hardened Steel smooth rod (choose 400mm length) for Z axis * 1 x Inductive Proximity Sensor - PNP * 1 x Genuine E3Dv6 or Clone (1.75mm long) with optional Block & Sock v6 Upgrade Print Settings: * 3 Perimeters * 3 top/bottom layers * 0.2mm layer height (or better) * 50% infill * No support required Print 1 of everything except the following parts: * 2 x Z_Carriage_v1.1 * 4 x Z_Carriage_Clamp_v1.1 * 4 x Z_Shaft_Clamp_v1.2 * 2 x XY_Clamp_v1.1 * 2 x XY_Joiner_v1.1 * 2 x XY_Idler * 3 x Y_Shaft_Clamp * 4 x Bed_Support_v1.1 Some useful extras: * HyperCube 3D Printer Accessory Pack * HyperCube CNC Toolheads * Various Z nut mounts for Integrated Leadscrew Motors * X-Axis 10mm Anodized Aluminum alternatives Notes: * Bed_Support_v1.1 is required for the revised bed configuration (build log video #11) * Z Endstop v1.1 is required for the revised bed configuration. * Z_Motor v1.1 and Z_Shaft_Clamp v1.1 are required for bottom-mounted motors * Fan_Duct v1.1 provides extra clearance for E3D silicone socks * Fan_Duct v1.2 is designed for easier bridge printing * X-Carriage v1.1 provides additional support to the belt mount. * XY Joiner/Clamp v1.1 supports longer bearing LM8LUU and dual LM8UU bearings. Configuration.h files have been updated to Marlin 1.1-RC8. Old file versions can be found on Thingiverse (http://www.thingiverse.com/thing:2013921). E3D (Inductive) Sensor Mount v1.1 provides improved sensor mount stability. New X_Carriage & E3D_Mount & E3D_Sensor_Mount designs allow for removable tool heads! Z-axis rails have been increased to 12mm diameter, and Z-axis parts have been updated. Marlin 1.1.9 Configuration.h files are included. Bowden parts have been added to this HyperCube kit. Bowden_Motor_v1.1 is designed for easier printing (62deg overhang). Consider supporting me on Patreon: https://www.patreon.com/Tech2C

With this file you will be able to print HyperCube 3D Printer/CNC with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on HyperCube 3D Printer/CNC.