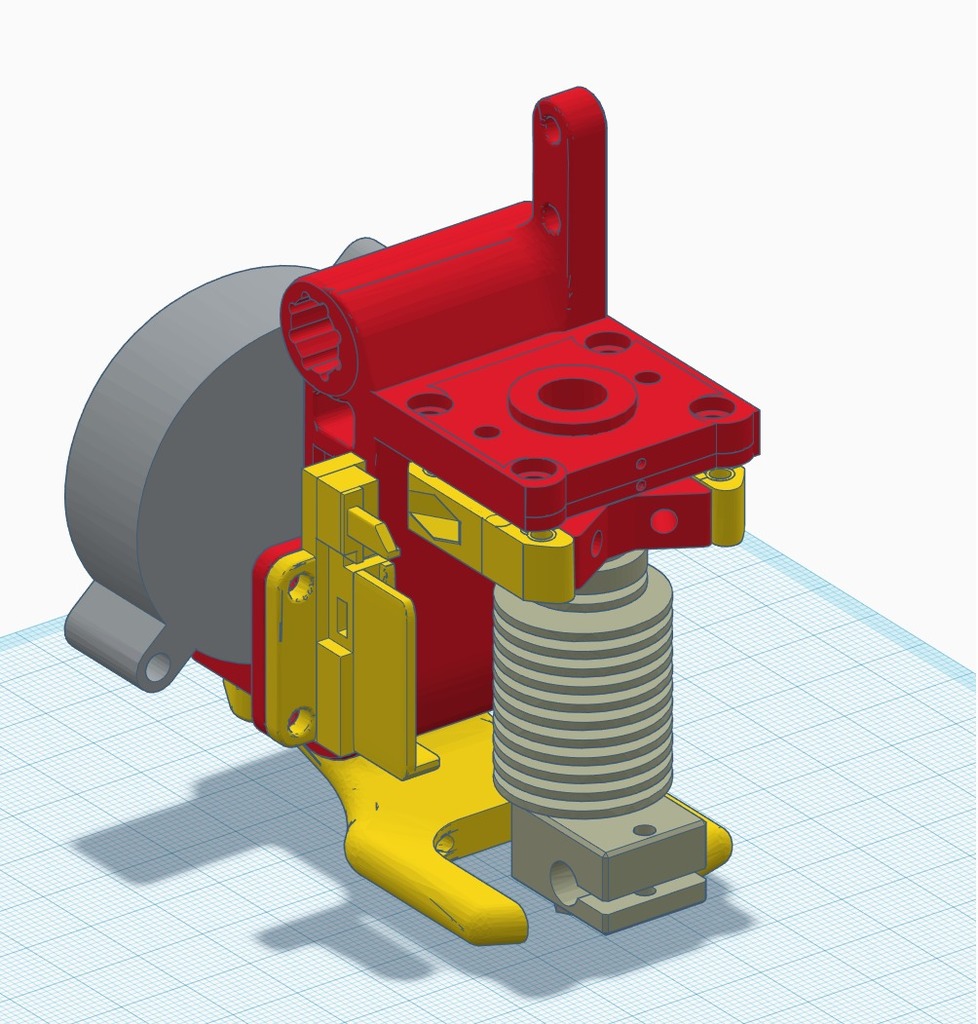

Hypercube 300 - Lite & Piezo Lite Carriage plus Other Mods

thingiverse

Update Aug 22, 2018: I've created both carriages on a tinkercad page with standard 10.00mm bore holes. If you need to change the bore hole size, copy to your own page, adjust dimensions of negative cylinder, combine, and save to stl. https://www.tinkercad.com/things/fceVjI97dml#/ If you don't have a tinkercad account, create one. Update Aug 16, 2018: I fixed two errors in the regular carriage pointed out to me. There was a tiny gap between the carriage and hotend part (.05mm) that showed up on the slicer, and screw hole for parts cooling fan was partially filled. Both are now fixed. Reverted to exactly 10mm for X rod holes. Update Aug 11, 2018: I moved X rod holes 3mm towards back to straighten XY belts. They came into carriage on an angle before. Added standard carrier with my adjustments (relocated X rod holes, sturdier fan shroud bracket) and increased size of X holes to 10.1mm. I combined top plate from piezo holder with HC300 Lite carrier, removed screw pins from back of clamp piece, and enlarged hole in piezo top plate to take a 9mm PTFE tube connector. Increased material around fan duct bracket slightly as it was brittle. Increased fan duct thickness by .25mm as it was too brittle for my liking and altered angle of screw tabs so it'll print easier (previously was ~40 degrees, now 60). The pillowblock bearing spacer and Z bearing holder are part of a single motor to dual leadscrew I'm working on. I fine-tuned integrated bushings: I use a 10mm drill bit, push it through (without turning) then slowly spin it a few times with a drill to knock any protrusions off the inside. If it still binds at all on X rods, I use a piece of 220 grit sand paper rolled into a tube, push through hole and spin 3 or 4 times and check fit again. Use a 9mm drill bit to tune PTFE connector hole. If it's too tight it'll crack the plastic. One note on assembly: The fan duct hole is slightly rounded, so when you print the fan, use a knife to shave off corner of side that's completely square to keep it from pushing against the hole. The piezo PCB holder mounts to holes for X end stop. It's for larger multi-piezo board. If you have smaller single-piezo board, I'll make a mount for that one soon. The rest of pieces are same, so you can get belt clamp for carrier from Hypercube 300 Lite X Carriage and other part of the piezo clamp from Piezo20 Hotend Z Probe.

With this file you will be able to print Hypercube 300 - Lite & Piezo Lite Carriage plus Other Mods with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Hypercube 300 - Lite & Piezo Lite Carriage plus Other Mods.