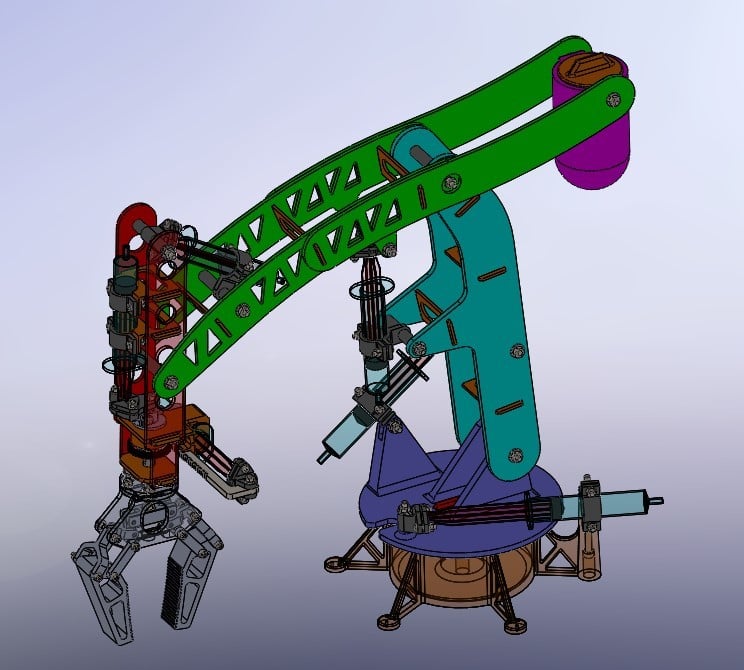

Hydraulic Robot Arm 6-Axis

thingiverse

This is a 6-axis hydraulic "robot" arm. The axes are actuated with 10ml syringes which function as cylinders, and 1/8" inside diameter flexible tubing. I saw several versions of these on social media, mostly made out of cardboard or kits with laser cut wood. I thought it would be cool to make my own with printed parts. As you can see below, getting this thing to work was a challenge. I've added a counterweight (fill with sand) to help it hold position better, but it's not perfect. All 6 axes are functional, but it doesn't always hold position very well. Redesigning the controller to be self locking somehow would be ideal, but I just don't have time right now. ***UPDATE 3/2/20*** I've added STEP files for the arm and the controller, with an improved version of the base in it. I don't know when I'll get around to making more improvements, but feel free to take the step files and do a remix. ***Update 11/4/2018*** I fully assembled and tested the arm today. It does work but the weight of the gripper pulls the arm down if you let go of certain levers, depending on the position. I have several ideas of how to fix this, including adding a counterweight to the arm, screwing the base and controller to a board (I also filled the base with pebbles for counterweight), and possibly re-designing the controller and adding valves to some of the axes for parking. All of this will take time to develop, and I'll keep it set to "work in progress" until I'm satisfied with it. Aside from the weight issue there weren't many other hang ups. Some of the holes were a bit tight and I just widened them out a bit with a drill bit. You can only access 4 of the 6 screws for the wrist, but 4 is plenty. ***Update 10/26/18*** I've ordered all the fasteners so I should have this thing built and tested sometime in early November. I'm going to give it a shot using 4mm wooden dowels instead of the M4 bolts, but I still had to buy all of the M3 stuff and the M4 threaded rod from the hardware list. I'm going to add printed retainers for the dowels and add an STL to print the large m4 washers for the pivot points on the arm linkages. ***Update 10/8/18*** I'm finished with the modeling and I'm starting to print parts. I've uploaded an STL of the entire assembly for reference to give you an idea of how it assembles. ***I have uploaded all the files for this thing.*** You could use 4mm wooden dowels for some of the fasteners to save money and glue on some sort of end caps. I would recommend using screws for the M3 fasteners though. This is a 6-axis hydraulic "robot" arm. The axes are actuated with 10ml syringes which function as cylinders, and 1/8" inside diameter flexible tubing. I saw several versions of these on social media, mostly made out of cardboard or kits with laser cut wood. I thought it would be cool to make my own with printed parts. As you can see below, getting this thing to work was a challenge. I've added a counterweight (fill with sand) to help it hold position better, but it's not perfect. All 6 axes are functional, but it doesn't always hold position very well. Redesigning the controller to be self locking somehow would be ideal, but I just don't have time right now. ***UPDATE 3/2/20*** I've added STEP files for the arm and the controller, with an improved version of the base in it. I don't know when I'll get around to making more improvements, but feel free to take the step files and do a remix. ***Update 11/4/2018*** I fully assembled and tested the arm today. It does work but the weight of the gripper pulls the arm down if you let go of certain levers, depending on the position. I have several ideas of how to fix this, including adding a counterweight to the arm, screwing the base and controller to a board (I also filled the base with pebbles for counterweight), and possibly re-designing the controller and adding valves to some of the axes for parking. All of this will take time to develop, and I'll keep it set to "work in progress" until I'm satisfied with it. Aside from the weight issue there weren't many other hang ups. Some of the holes were a bit tight and I just widened them out a bit with a drill bit. You can only access 4 of the 6 screws for the wrist, but 4 is plenty. ***Update 10/26/18*** I've ordered all the fasteners so I should have this thing built and tested sometime in early November. I'm going to give it a shot using 4mm wooden dowels instead of the M4 bolts, but I still had to buy all of the M3 stuff and the M4 threaded rod from the hardware list. I'm going to add printed retainers for the dowels and add an STL to print the large m4 washers for the pivot points on the arm linkages. ***Update 10/8/18*** I'm finished with the modeling and I'm starting to print parts. I've uploaded an STL of the entire assembly for reference to give you an idea of how it assembles. ***I have uploaded all the files for this thing.*** You could use 4mm wooden dowels for some of the fasteners to save money and glue on some sort of end caps. I would recommend using screws for the M3 fasteners though. Here are some tips: 1. Make sure you fill the syringes with the correct amount of water. The gripper syringe should only be filled about 3ml, while all the other syringes use 10ml of water. 2. Use nylon lock nuts in the locations where the M4 bolts and M3 bolts on the gripper links need to be a little loose. 3. Pay attention when assembling the tabs for the frame pieces, as they fit together tightly and permanently. 4. Consider using 4mm wooden dowels instead of most of the M4 hardware to save money. 5. Use a smaller nozzle and slow speeds when printing the rack and gear. This will help you get the best results with your hydraulic "robot" arm.

With this file you will be able to print Hydraulic Robot Arm 6-Axis with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Hydraulic Robot Arm 6-Axis.