How to Measure Nozzle Opening Size (accurately)

thingiverse

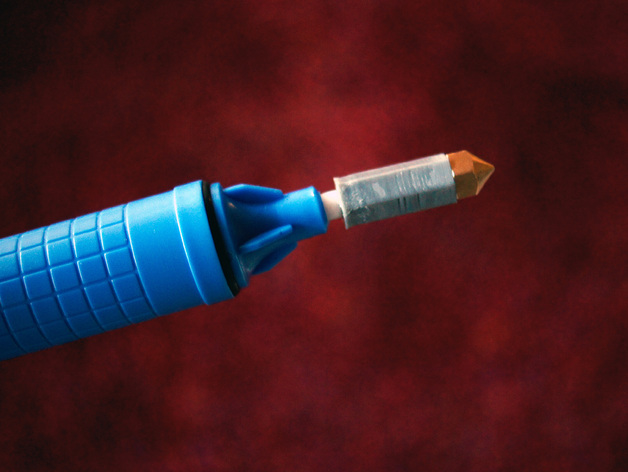

It can be tricky to tell how big your 3D printer's nozzles are--the holes are extremely small and can't be measured easily (0.2-0.5mm). After cleaning nozzles, different sizes can get mixed together. Even if they are labeled, the labels can wear off or become obscured. Sometimes nozzle openings can become larger or wear away from using metal or abrasive filaments. Or maybe you make your own nozzles and would like to test your results. This is a test I devised for checking unknown nozzle sizes against a few known samples. It works by pushing a consistent volume of air through the nozzle with a consistent force, and measuring the time it takes. It's not super accurate, but you should be able to determine the size within 0.05mm or better. You need A good solder-pult / solder sucker A stopwatch A few nozzles of known size This printed adapter Maybe some grease or sealant Decent reaction time How to use Take a solder-pult (aka solder sucker, desoldering pump) and make sure it works well -- doesn't stick or leak. It should release smoothly and consistently. Put your finger over the business end. Release it. It should hold the vacuum (with the plunger not moving) for at least ten seconds. If it doesn't, clean it out, change the o-rings, re-oil, etc. until it does. Put this printed adapter on the sucker and screw in a nozzle of a known size. (the adapter is M6x1) Do the finger test again. If it doesn't hold, put some grease or sealant in the adapter on both ends until it does. To get an accurate result, we need all the air to travel through the nozzle and not from leaks. Solder suckers will have different spring strengths and barrel sizes. Maybe you're miles underground with cold heavy moist air, or on Mars with very thin air, etc. We need to start with some baseline measurements. Push in the plunger -- slowly. If you ram it fast, the nozzle adapter will likely fly off, bust its seal, etc. Using a stopwatch, measure how long it takes for the plunger to release. Take a couple of measurements. Repeat using a few different (but known) size nozzles. Enter the data to make a chart correlating time vs nozzle size (Excel was able to give me a formula so I could calculate what other nozzles should be, extrapolating outside my range of known sizes) Next, I will make a jig to hold the sucker and some software to measure the plunger release time much more accurately / consistently.

With this file you will be able to print How to Measure Nozzle Opening Size (accurately) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on How to Measure Nozzle Opening Size (accurately).