How to fit Rectangular Material in a Tri-Clamp Lathe

thingiverse

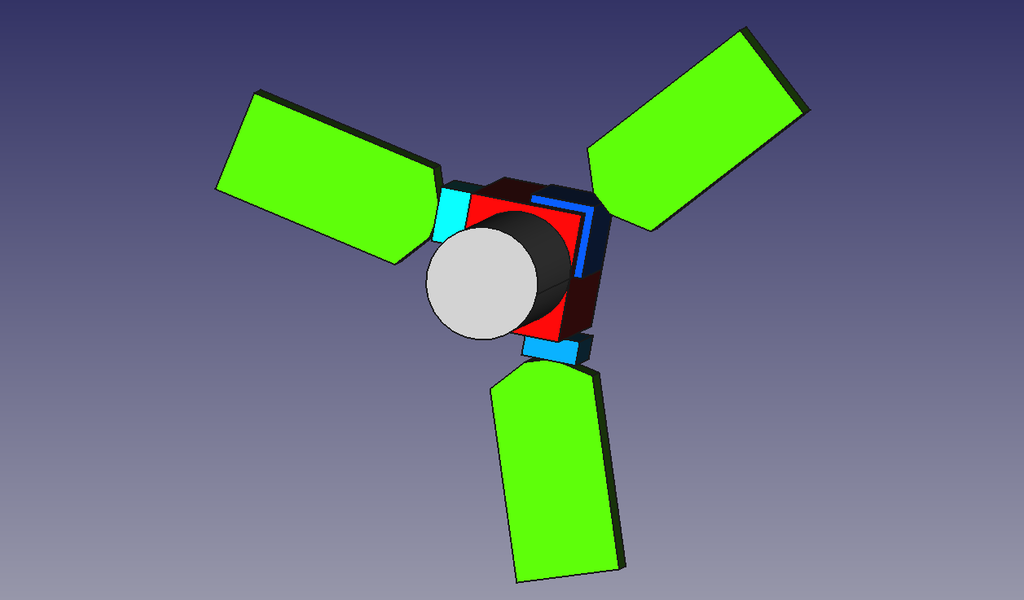

Let suppose you have a rectangular shaped (rest of) material, you want to produce a cylinder or tube of that same material, and want to do so asap and with the least amount of waist as possible...on a tri-clamp lathe... Then this calculation tool might come in handy: - enter the rectangular dimensions - enter if you will be using a corner profile in case of soft material In the Excel-spreadsheet and in the FreeCAD spreadsheet the clamp extra's will be calculated, and shown visually (also in a technical drawing). I have used it to maximize the amount of PTFE rings from a circular-segment-shaped block. Limit to the calculation is if the rectangular height is more than twice the width...then you should cut/saw the piece length-wise.

With this file you will be able to print How to fit Rectangular Material in a Tri-Clamp Lathe with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on How to fit Rectangular Material in a Tri-Clamp Lathe.