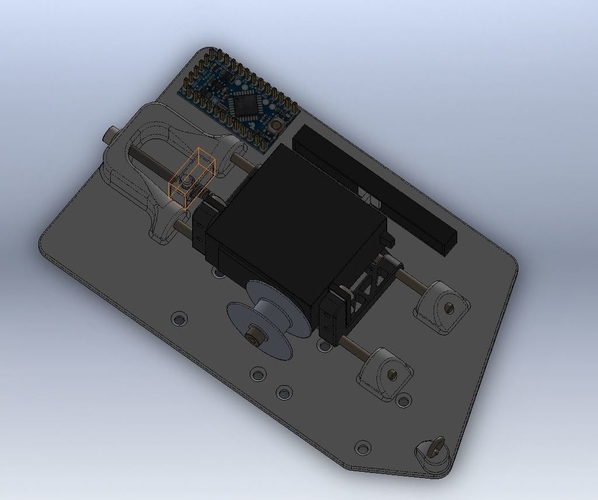

Hot Wire Cutter Tensioner V2

pinshape

This is a variant of the other tensioner I made for CNC hot wire cutter, designed to maintain even hot wire tension as the axes on the CNC machine move. It builds less in height compared to others but serves its purpose effectively. A modified servo rotates 360 degrees and an Arduino Pro Mini controller is used to manage it. The code is simple, and one thing that might need changing is the "map(a,b,c,d)" command to suit specific needs. Code follows below. #include Servo servo; const int potPin = A0; const int servoPin = 5; const int LED = 13; void setup() { pinMode(potPin, INPUT); pinMode(servoPin, OUTPUT); servo.attach(servoPin); // Serial.begin(9600); for testing purposes only. } void loop() { int potAngle = analogRead(potPin); potAngle = map(potAngle, 0, 800, 0, 180); // Adjusting the potentiometer range for centralization. servo.write(potAngle); if (potAngle == 90) { // Indicating when the servo is centered and stationary. digitalWrite(LED, HIGH); } else { digitalWrite(LED, LOW); } // Serial.println(potAngle); for testing purposes only. delay(15); // Normal speed; adjusted to 200 during testing.

With this file you will be able to print Hot Wire Cutter Tensioner V2 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Hot Wire Cutter Tensioner V2.