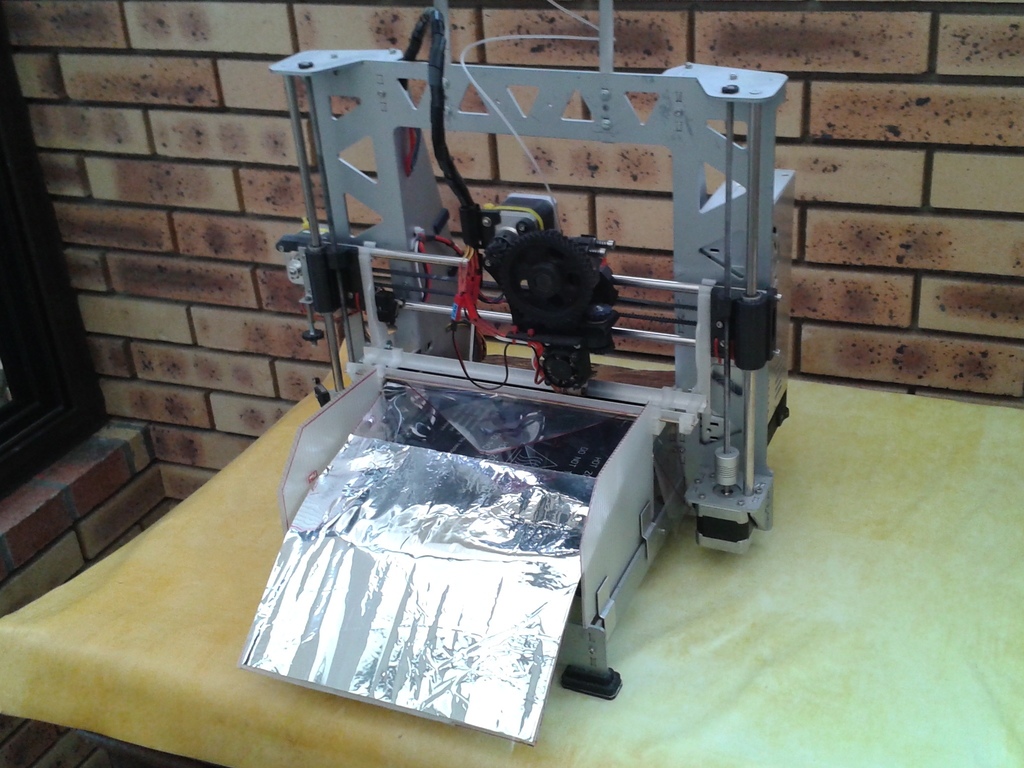

Hot Bed Enclosure V3

thingiverse

Issues of warping and cracking in ABS printing can be easily resolved using a Heated Build Chamber. This type of chamber is quite bulky, and all printer components (plastics, electronics) undergo high temperatures. The proposed solution involves building a heated enclosure around the hot bed instead of the entire printer. This approach offers several benefits. Printer parts, including electronic components and motors, operate at room temperature with this setup, eliminating the need for extra heating. Additionally, power consumption is significantly reduced - up to 50% less than usual - as less energy is required to heat the bed. The enclosure consists of three main components: two insulation sheets covering the entire hot bed, two side plates attached to the printer frame, and two Z shutters that follow the movement of the X axis. Insulation sheets (upper covers) and shutters are fixed to a support made from aluminum angles and plastic parts, which is itself attached to the X axis rods. Front and rear covers consist of three layers: mylar film, PE foam, and aluminized plastic film. For more information, watch this video: https://youtu.be/211JHkUjk4k This design is an improved version of previous ones: www.thingiverse.com/thing:997467 www.thingiverse.com/thing:911708 New features include improved insulation, a simple and easy installation process (no screws required), and adjustable angle distance. The X shutters from the previous designs have been eliminated, and the distance between the angles has been reduced to minimize heat loss.

With this file you will be able to print Hot Bed Enclosure V3 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Hot Bed Enclosure V3.