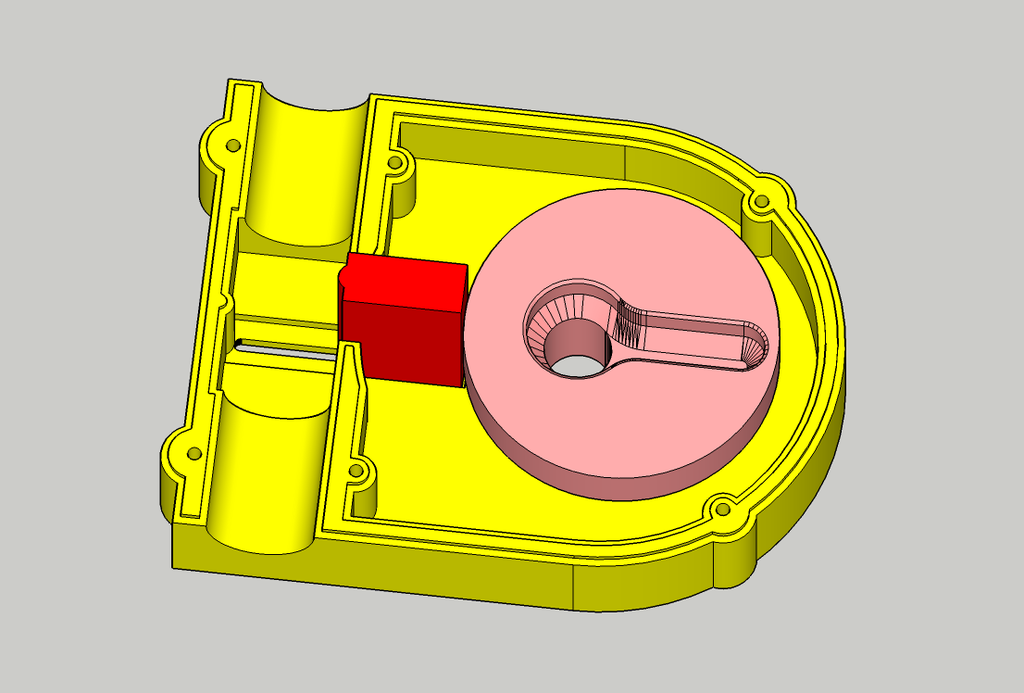

Hose pinch valve with servo for silicone tube 16mm

thingiverse

First prototype for testing the continuous use. Designed for automated dosing hot juice (80°) in bigger amounts, so later there is a more heat resistant material needed. Once closed, the valve stays tight, even if the power to the servo is cut. In closed position (~152°) the servo is still drawing up to 200mA because it barely does not reach the desired position. A curved design for the slider (pinching more at top and bottom), a bearing in the slider and/or a different curve of the excenter part could help preventing this, even though there is no problem stalling the motor. Its getting just slightly warm. Thinner tubing with 1mm wall would help also and is available in china, but isnt very common and maybe not as durable. I used a DS3225MG Servo with metal gears and a 25T aluminium servo arm. One with plastic gears did not survive. The silicone tube is OD 16 ID 12. The max. travel of the slide is 13mm. I used 3x30mm wood screws for the housing. Later improvemets (maybe): Bearing for the excenter part Small bearing in the slider to reduce friction and wear optimize curve of the excenter (more slider travel per degree in the beginning, less in the last degrees to raise pinching force and prevent stalling the servo)

With this file you will be able to print Hose pinch valve with servo for silicone tube 16mm with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Hose pinch valve with servo for silicone tube 16mm.