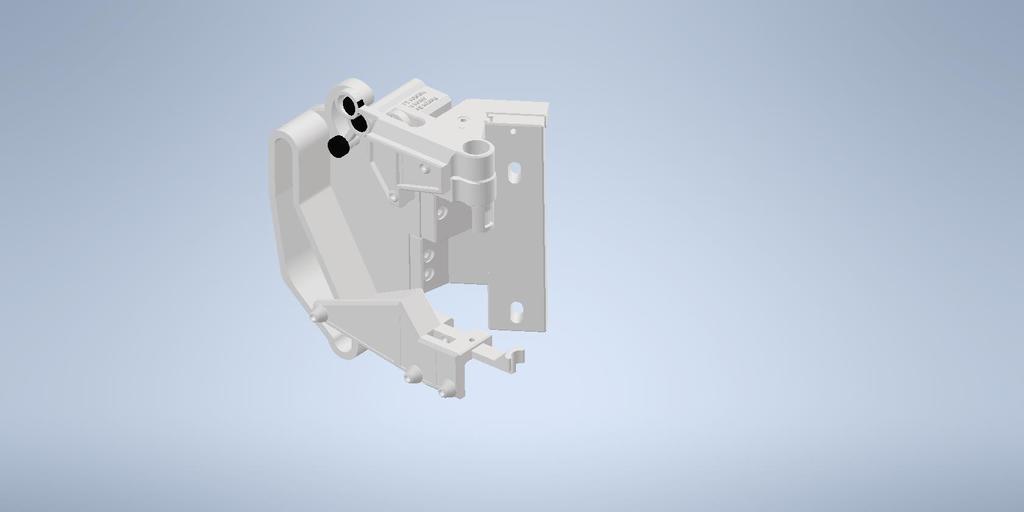

Hornady AP Case Feeder - Bearing Based - V1.0

thingiverse

*NOTE Version 2 will now be for sale. It will not be available on Thingiverse. It has taken much longer to develop, test, and required that I purchase a new printer. Everything about V2 is new except for the bracket and pattern. It has additional supports for the tube feeder, and it allows for the tube feeder to be removed for loading/unloading, which also allows the user to have multiple loaded for long loading sessions, or dedicated lube / unlubed cases. It also introduces caliber specific drop tubes and can accommodate much taller cases than previously. V1 will remain available for personal use; however, if any parts made by other users are made to be unavailable I will not provide them. *you may purchase the V2 stl files for $25. I don’t care how many you print for friends, but it cannot be used for commercial use. I will also include a inventor file of the feed tube so you can load any cartridge you want by modifying and printing that file.* I am also considering sourcing the hardware and selling that as a package if there is interest.* This is a case feeder for the Hornady Lock and Load AP press, Inspired by the design by Bartje64. While the design was influenced by Barteje64's, all of these components were created new (from scratch) in Autodesk Inventor. This design still utilizes their case selector V5 (https://www.thingiverse.com/thing:3844226/files), so you will need to print theirs to optimize the use of this print, otherwise a tube cut to the desired length could be substituted. You will also need to work out the hardware to mount their component (I used a scrap machine screw with the correct head diameter). A future revision to this design will be to replace their case selector completely, but for now it is functional enough. This was designed because I only have a SLA printer (Creality L002R) and the friction between the parts of the available designs was too great for the print to operate. also, this pulls the case slider straight back, rather than from the side of the slider, reducing any lateral torque on the press arm/slide itself. This design relies on 624zz bearings to function and operates with a bell and post style actuator rather than the vertical push-post style found on available designs. I believe this greatly reduces stress and friction applied to the upper components of the assembly. Another important difference is the geometry of the slider guide. By increasing the retraction angle of the lower slider, its path is much more gradual, which decreases stress on the assembly. Previous versions use the same approach decent path (as does the wire for Hornady's case feeder) but when relying on plastic this is an enhancement in my opinion. IMPORTANT - This is intended to be available for public use, but not for commercial use. Anyone seeking to print these for profit is requested to contact me before proceeding (the answer will probably be yes, we would just need to agree on a nominal royalty). I can only authorize the creation and sale of my files, no others. Build list (Links at bottom of page) 7 Tube Base 7 Tube Bottom 7 Tube Top REQUIRES - 7 Lee Tubes, 1 M4x25 screw, spring (cut) and washer) -Tubes press fit (press fit into top first. Once the tubes are press fit into bottom this difficult to remove) - 7 tube base requires M4x45mm bolt with M4 nuts to clamp against base of 7 tube base and to connect to Upper Slide Guide. -M4x25 screw with washer and cut to fit spring hold 7 tube top to 7 tube base. Leave enough room for base to separate from bottom under spring tension. Bearing Mount Top REQUIRES - 3 M4x25 screws and 1 624zz bearing. -Screw secures bearing to part -2 screws attach part to Upper Slide Guide Bell and Post Pivot REQUIRES - 1 624zz bearing and 2 M4x25 screws. - screws secure 1 bearing to part (bearing on outside of bottom hole) and the bearing inserted into Upper Slider to Bell and Post Connector (bearing on outside of upper hole. - this assemble press fits onto bearing attached to Bearing Mount Top Case Drop Guide - press fits into bottom of Upper Slide Guide Case Feeder Bracket REQUIRES - 2 1/4x20mm bolts, 2 1/4" washers. -use hardware to attach completed assembly to press. Case Pusher -Press fits into Lower Slide Roller. A hole is present for a screw if fitment is loose. Lower Slide Roller REQUIRES - 6 624zz bearings and 4 M4x25mm screws. -2 inner pockets both have a bearing held by one screw. -Lower holes have one bearing each held by one screw respectively (mount from inside). -Rear of roller has 2 bearings attached using one screw. This is intended to better align the force with the center of the slider, but a single bearing may work as well. Slide Roller Guide REQUIRES - 4 M4x25mm screws. -Slide Roller Guide mounts to back of Case Feeder Bracket Upper Slide Guide REQUIRES - 3 M4x25 screws, Spring - One screw secures Upper Slide Guide to back of Case Feeder Bracket - 2 screws secure Upper Slide Guide to top of Case Feeder Bracket - Spring goes inside Upper Slide Guide and will be compressed by screw inside of Upper Slide Roller Upper Slide Roller Requires - 3 624zz bearings, 3 M4x20mm angle head screws, and 2 M4x25mm screws. - 2 bearings mount to inside of slider using M4x20 screws. - 1 bearing mounts to bottom of roller using M4x20mm screw (this must be done with Upper slide quide detached from Case Feeder Bracket. - 1 M4x25mm screw connects Upper Slider to Bell and Post Connector to rear of Upper Slide Roller - 1 M4x25mm screw goes through top of Upper Slide Roller and compresses spring within Upper Slide Guide. Upper Slide to Bell and Post Connector Requires - 2 624zz bearings Bearings press fit into Connector Parts List 1/4x20mmx3/4"bolts (2) 1/4" washers (2) 1/4"x4.5in (or longer) hex bolt (1) 7/32 x 1-5/8 x 0.015 spring (Picked mine up at lowes) -I also used a 5/16x1-1/2x0.20 spring around that one but it probably wasn't necessary. M4x20mm oval head - This style but only (3) needed - https://www.amazon.com/Recessed-Machine-Stainless-Fasteners-ASMM31664/dp/B00BNCRFIE/ref=sr_1_1?dchild=1&keywords=Screws&pd_rd_r=d27f3a9f-a5ee-4ec2-adf5-79e2715a767f&pd_rd_w=YYa16&pd_rd_wg=zDGVJ&pf_rd_p=91473338-a775-4a82-9600-6767cae1f29a&pf_rd_r=1E0J4Q6QT0QYCFYGNRPG&pid=3Hm1qHI&qid=1610417631&refinements=p_n_feature_two_browse-bin%3A2292871011%2Cp_n_feature_twenty-eight_browse-bin%3A19043892011%2Cp_n_feature_five_browse-bin%3A3177285011&s=industrial&sr=1-1 M4x25 screws (19 pan head) - https://www.amazon.com/FixtureDisplays-Socket-M4x25mm-Screws-15168-20PK-NF/dp/B0872NQBS7/ref=sr_1_3?dchild=1&keywords=m4x25mm+screws+20&qid=1610417373&sr=8-3 624zz bearings (13 required) - https://www.amazon.com/XiKe-624ZZ-Pre-Lubricated-Performance-Cost-Effective/dp/B07JHKK44G/ref=sxts_sxwds-bia-wc-nc-drs1_0?cv_ct_cx=624zz&dchild=1&keywords=624zz&pd_rd_i=B07JHKK44G&pd_rd_r=d3d97249-f979-4aab-98cf-8585044e39ff&pd_rd_w=9Ak5F&pd_rd_wg=7uWVB&pf_rd_p=a64002b9-9c26-4361-b8a1-b0f5a4835670&pf_rd_r=XYSSMP2XG2T0EBNMES0D&psc=1&qid=1610414408&s=industrial&sr=1-1-38d0a374-3318-4625-ad92-b6761a63ecf6 Lee tubes https://www.amazon.com/LEE-PRECISION-90661-Load-Master-Progressive/dp/B000N8JWEO/ref=sr_1_1?dchild=1&keywords=lee+tubes&qid=1610419915&sr=8-1

With this file you will be able to print Hornady AP Case Feeder - Bearing Based - V1.0 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Hornady AP Case Feeder - Bearing Based - V1.0.