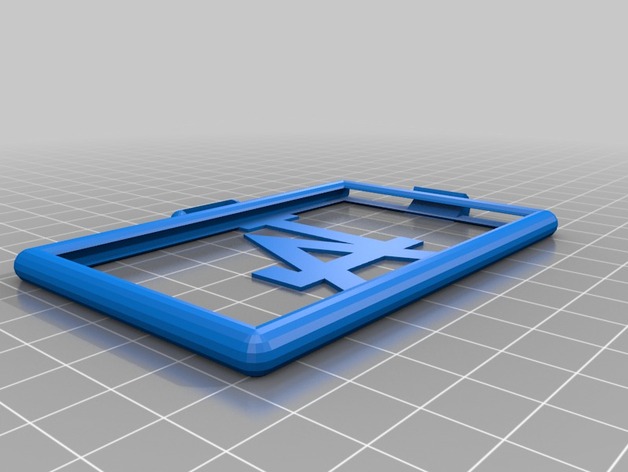

Horizontal Card Badge - LA Dodgers

thingiverse

A coworker at work requested something related to the LA Dodgers, but I thought simply printing the logo would be dull. Then he damaged his card holder.\nI had previously printed a badge holder that was somewhat flimsy because its back is so thin. It's not possible to thicken just the back since then the clip will either be too thick or fall off the build plate, and I'm sensitive to supports.\nAdding the LA logo to the back makes it less fiddly, and also kills two birds with one stone.\nPrint Settings\nPrinter: \n Folger Tech Kossel Rev B\n \n Rafts: \n No\n \n Supports: \n No\n \n Resolution: \n 0.2mm\n \n Infill: \n 100%\n \n Notes: \n I would avoid using rafts unless you really need them due to a perforated plate or an unlevel build plate. The back of the holder is very thin, so it will be hard to recover from the air gap and won't turn out well. If you don't need the air gap because you're using soluble supports, you can do anything you want since you have special plastic that can fix all of the flaws.\nActual infill doesn't matter; just do 3 or 4 perimeters and it's solid. It's not very thick a piece.\nThe original version of the badge required some scaling down, but I've already done that. If your printer isn't far off (printing too large or small), it will hold a card.\nI wouldn't print this in PLA. Getting the card requires quite a bit of flexing of the retaining tab, so more flexible plastic like ABS or PETG would be better. I use ABS and it's worked perfectly. Further, an ID badge is something you might leave in your car by accident or design, and PLA deforms very quickly in summer car temperatures. It's possible that the PLA will flex enough due to the thin back/tab - I just wouldn't bother because of the many shortcomings of PLA for this purpose. Similarly, I wouldn't do this in a truly flexible plastic like TPU or Ninjaflex. It's not needed, and could work against what you're trying to achieve.\nPost-Printing\nThe little flap that holds the card usually needs a little help opening up the first time. I use a very small blade screwdriver to wiggle it loose.\nIf your printer isn't great at bridging, you will probably have some dangles. There is some play in the slot for the card, so you might try leaving them and test fit your card. If you clean them out, be gentle.\nHow I Designed This\nUse 3D Builder, Smoosh Together\n I've tried modifying parts with Blender and Meshmixer before, but nothing has been as easy as the 3D Builder program. It's like using TinkerCAD but with STL files. I've been able to get Blender or Meshmixer to do what I wanted while 3D Builder has been just as easy as TinkerCAD. I dislike Windows 10, but I'm loving the 3D Builder.\nI scaled down the badge holder to make it "correct" as suggested by the original creator. Then I scaled the logo keeping x and y (and z) locked to fit it on the back of the holder, then when I got it all set and aligned how I wanted it, I unlocked the scaling and made the z match the height of the back of the holder. Finally I merged the parts and saved the STL.

With this file you will be able to print Horizontal Card Badge - LA Dodgers with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Horizontal Card Badge - LA Dodgers.